FISH FILLETING MACHINE

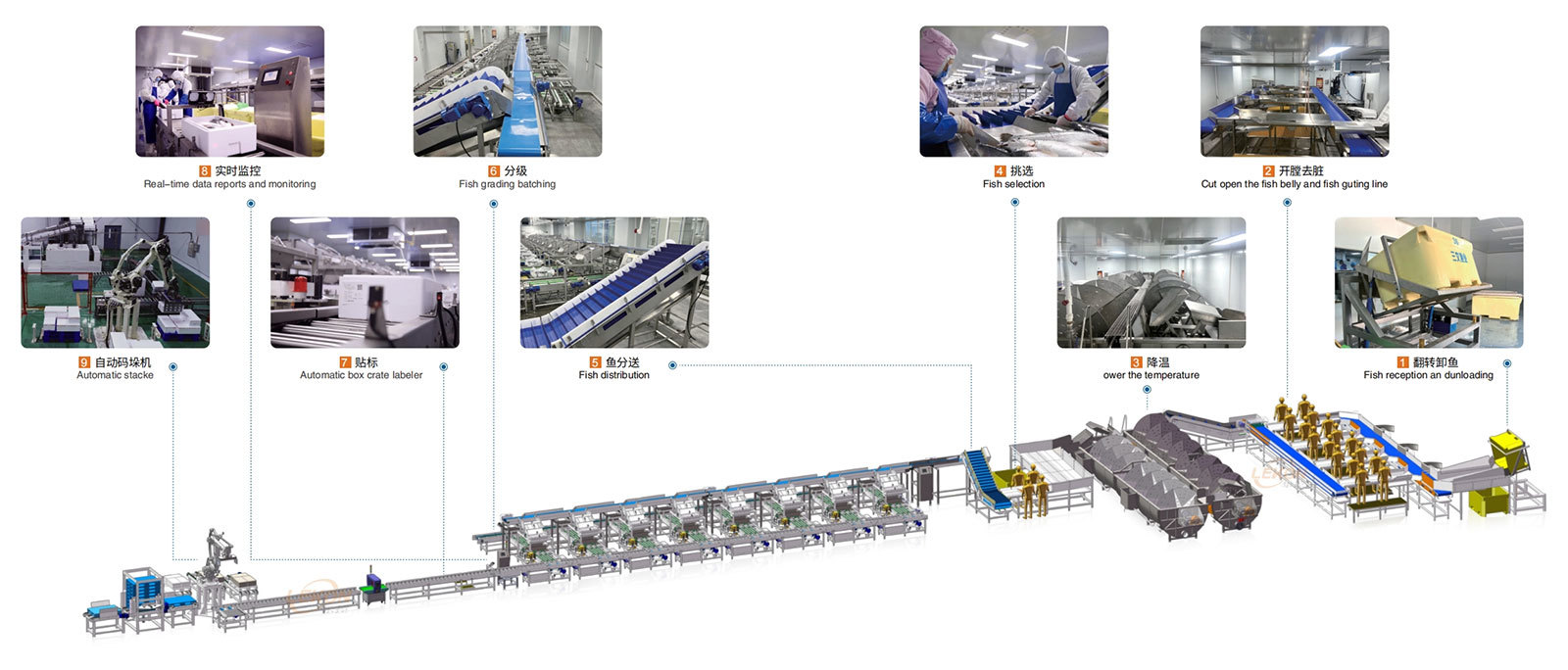

Sea Food Production Process and Core Equipment

18 Mar,2025

The production process of seafood involves several key steps, each requiring specific equipment to ensure safety, quality, and extended shelf life. Here's an overview of the production process along with JASIMA’s core equipment used:

1. Raw Material Inspection and Preparation:

Inspection Equipment: Instruments to assess the quality and temperature of incoming seafood, ensuring it meets production standards.

Processing Equipment: Machines such as fish graders and conveyors to clean, trim, and cut the seafood into appropriate sizes for further processing.

2. Cleaning and Evisceration:

Eviscerating Machines: Automated systems that remove internal organs from fish, ensuring hygiene and product quality.

VACUUM SUCTION COLLECTION SYSTEM

Washing Systems: High-pressure water jets or tumbling machines to thoroughly clean the seafood.

ROTARY DRUM WASHING MACHINE

3. Filleting and Skinning:

Filleting Machines: Precision cutters that separate the flesh from the bones, producing uniform fillets.

Skinning Machines: Devices that remove the skin from fillets, ensuring a clean, consistent product.

FISH SKINNING MACHINE

4. Grading and Sorting:

Grading Machines: Automated systems that sort seafood based on size, weight, or quality, ensuring uniformity in the final product.

ROTARY TRAY WEIGHT GRADER

5. Preservation:

Freezing Equipment: Blast freezers or plate freezers that rapidly freeze seafood to maintain freshness and extend shelf life.

SPIRAL CHILLING AND BLEEDING TANK

Canning Machines: For products like canned fish, these machines fill, seal, and sterilize cans to ensure product safety.

6. Packaging:

Packaging Machines: Vacuum sealers or modified atmosphere packaging systems that protect the seafood from contamination and preserve its quality.

7. Storage and Distribution:

Cold Storage Facilities: Refrigerated warehouses that maintain optimal temperatures for storing seafood products.

Transportation Equipment: Insulated containers and refrigerated trucks to ensure the seafood remains at the correct temperature during transit.

SALMON WHITE FISH PRIMARY PROCESSING

Related Information

抱歉~

无相关内容