BONE DICER

Canned Meat Production Process and Core Equipment

18 Mar,2025

The production of canned meat products involves several key steps, each requiring specific equipment to ensure safety, quality, and extended shelf life. Here's an overview of the production process along with JASIMA’s core equipment used:

1. Raw Material Inspection and Preparation:

Inspection Equipment: Instruments to assess the quality and temperature of incoming meat, ensuring it meets production standards.

Processing Equipment: Machines such as meat saws and grinders to clean, trim, and cut the meat into appropriate sizes for canning.

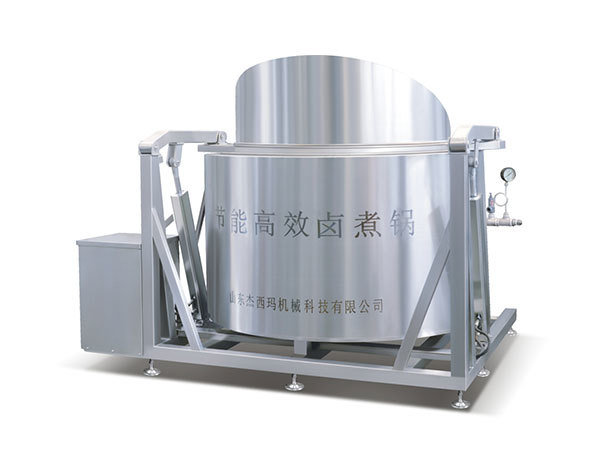

2. Cooking:

Cookers/Retorts: Large industrial cookers or retorts are used to heat the meat to specific temperatures, effectively killing harmful microorganisms.

3. Filling:

Filling Machines: Vacuum fillers are employed to portion the cooked meat into cans. These machines ensure accurate portioning and maintain product consistency.

4. Sealing:

Seaming Machines: Double seamers create airtight seals between the can body and lid, preventing contamination and preserving the product.

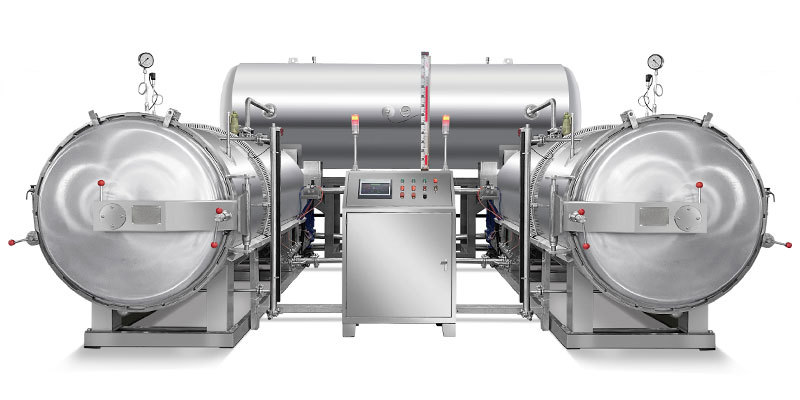

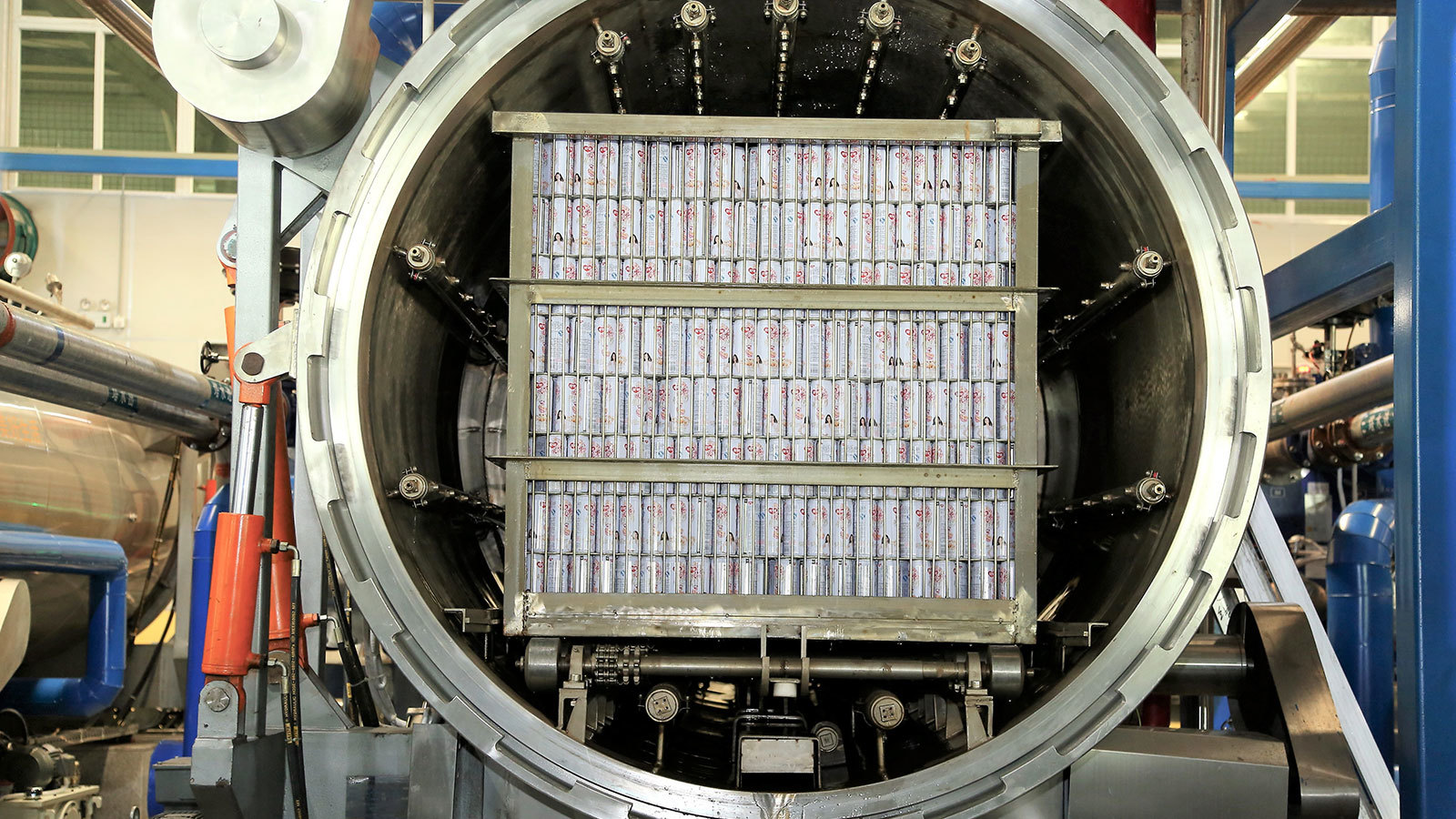

5. Sterilization:

Retorts: After sealing, cans are placed in retorts—pressurized cooking vessels—to achieve sterilization. This process involves heating the cans to temperatures above the boiling point of water, typically between 116–130°C, to eliminate any remaining pathogens.

HREE PAN SERIES WATER-BATH TYPE RETORT

6. Cooling:

Cooling Systems: Post-sterilization, cans are rapidly cooled using water or air cooling systems to halt the cooking process and prevent overcooking.

7. Labeling and Packaging:

Labeling Machines: Automated systems apply labels to the cans, providing product information and branding.

Packaging Lines: Cans are grouped into cartons or cases, ready for distribution.

Related Information

抱歉~

无相关内容