Category

Share to

Ultra Low Nitrogen Fully Premixed Steam Generator

Still deciding? Get samples first, Contact US !

View similar products

- Details

-

Product Introduction

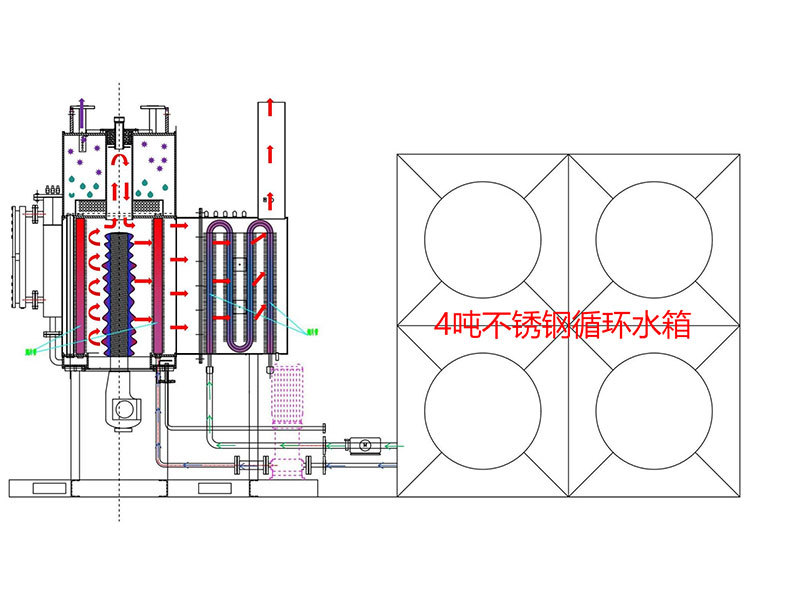

Fully premixed steam generation technology - The process of steam generation in traditional cooking equipment is: water storage - heating - water boiling - steam generation. The fully premixed steam generator utilizes its own "steam generation technology" to instantly generate steam from a single fin heat exchanger in tap water, achieving steam output within 2 minutes of start-up. This not only saves resources but also greatly reduces heat loss. A steam boiler needs to pass through a pressure vessel to generate steam pressure before it can produce high-temperature steam. A fully premixed steam generator directly produces high-temperature steam without the need for a pressure vessel to generate steam pressure.Product Advantages

a、 No approval required, no annual inspection required;

b、 Low heat loss and energy consumption, saving more than 30% energy compared to traditional gas boilers;

c、 Fast heating rate, adjustable steam temperature from 120°C to 180°C;

d、 One click start, no need for multiple modules to start and stop simultaneously, fully intelligent management, precise temperature control, no need for human supervision;

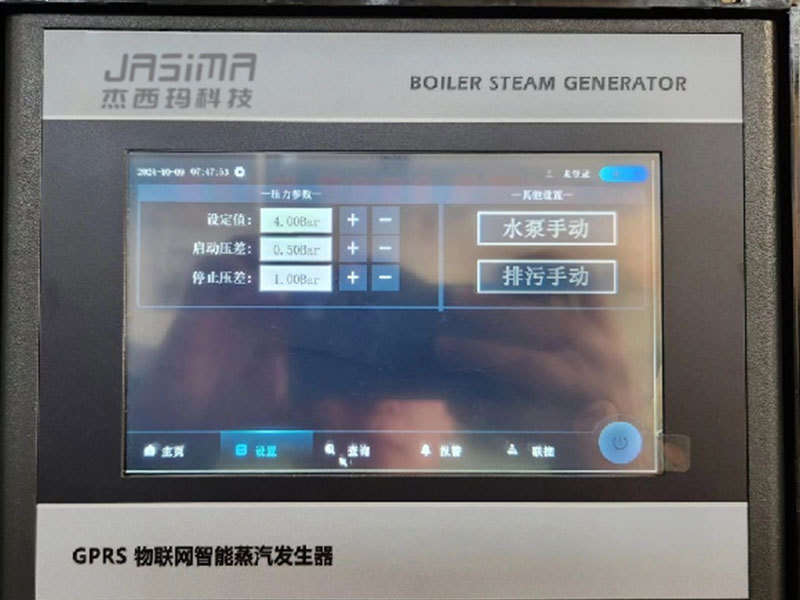

e、 IoT programmable technology enables intelligent control and real-time data monitoring;

f、 The high-efficiency condensing fins are made of 316 stainless steel, which is corrosion-resistant, anti-oxidation, and has a long service life;

g、 Environmental compliance standards, lower than the standard of "Notice on Implementing Air Pollutant Emission Control Values in Key Control Areas of the City", below 30mg/m3;

h、 The footprint is only 1/5 of traditional boilers, and one person can move it;

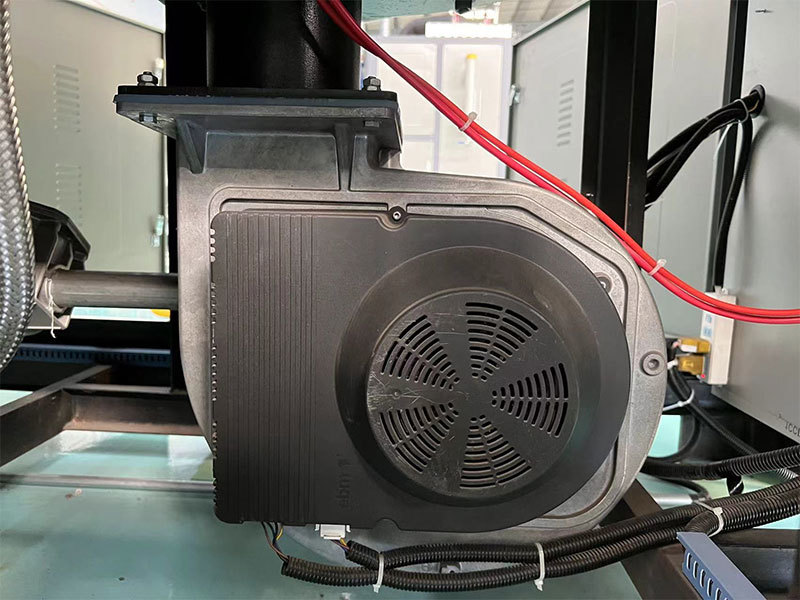

i、 Using German EBM fans and Troon valve groups, high-end configurations ensure both quality and durability;

j、 National authoritative institution testing report, no need for annual inspection, no need for security inspection review;

k、 Thermal efficiency 93.23%; 40% energy-saving compared to similar products;

l、 Infinite variable speed regulation: No need for repeated start stop, can be accurately adjusted to 0.01MPa according to the end pressure, and can continuously produce steam (20% -100%);

Ultra Low Nitrogen Fully Premixed Steam Generator

Still deciding? Get samples first, Contact US !

Tag list

Products Category

- Details

-

Product Introduction

Fully premixed steam generation technology - The process of steam generation in traditional cooking equipment is: water storage - heating - water boiling - steam generation. The fully premixed steam generator utilizes its own "steam generation technology" to instantly generate steam from a single fin heat exchanger in tap water, achieving steam output within 2 minutes of start-up. This not only saves resources but also greatly reduces heat loss. A steam boiler needs to pass through a pressure vessel to generate steam pressure before it can produce high-temperature steam. A fully premixed steam generator directly produces high-temperature steam without the need for a pressure vessel to generate steam pressure.Product Advantages

a、 No approval required, no annual inspection required;

b、 Low heat loss and energy consumption, saving more than 30% energy compared to traditional gas boilers;

c、 Fast heating rate, adjustable steam temperature from 120°C to 180°C;

d、 One click start, no need for multiple modules to start and stop simultaneously, fully intelligent management, precise temperature control, no need for human supervision;

e、 IoT programmable technology enables intelligent control and real-time data monitoring;

f、 The high-efficiency condensing fins are made of 316 stainless steel, which is corrosion-resistant, anti-oxidation, and has a long service life;

g、 Environmental compliance standards, lower than the standard of "Notice on Implementing Air Pollutant Emission Control Values in Key Control Areas of the City", below 30mg/m3;

h、 The footprint is only 1/5 of traditional boilers, and one person can move it;

i、 Using German EBM fans and Troon valve groups, high-end configurations ensure both quality and durability;

j、 National authoritative institution testing report, no need for annual inspection, no need for security inspection review;

k、 Thermal efficiency 93.23%; 40% energy-saving compared to similar products;

l、 Infinite variable speed regulation: No need for repeated start stop, can be accurately adjusted to 0.01MPa according to the end pressure, and can continuously produce steam (20% -100%);

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!