Category

Share to

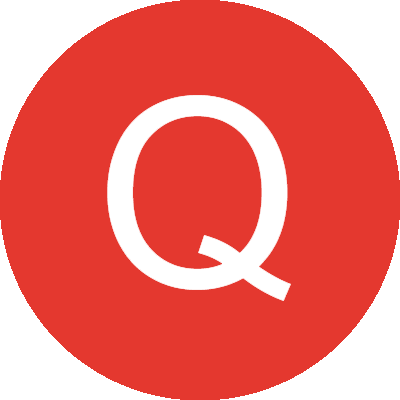

Blanching line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

Product Description

A blanching line is an essential piece of equipment in the food processing industry, particularly for vegetables and fruits. The primary purpose of blanching is to inactivate enzymes that can cause spoilage, to clean the product, and to prepare it for further processing such as freezing or canning. The blanching process typically involves briefly heating the product in hot water or steam, followed by rapid cooling.Product Parameters

Capacity

Blanching lines can vary significantly in capacity, ranging from small-scale units processing a few hundred kilograms per hour to large industrial lines capable of handling several tons per hour.

Temperature Control

Precise temperature control is crucial, with typical blanching temperatures ranging from 70°C to 100°C (158°F to 212°F).

Heating Medium

Options include hot water or steam, with steam being more energy-efficient and faster.

Cooling System

After blanching, the product is usually cooled using cold water or air to halt the cooking process.

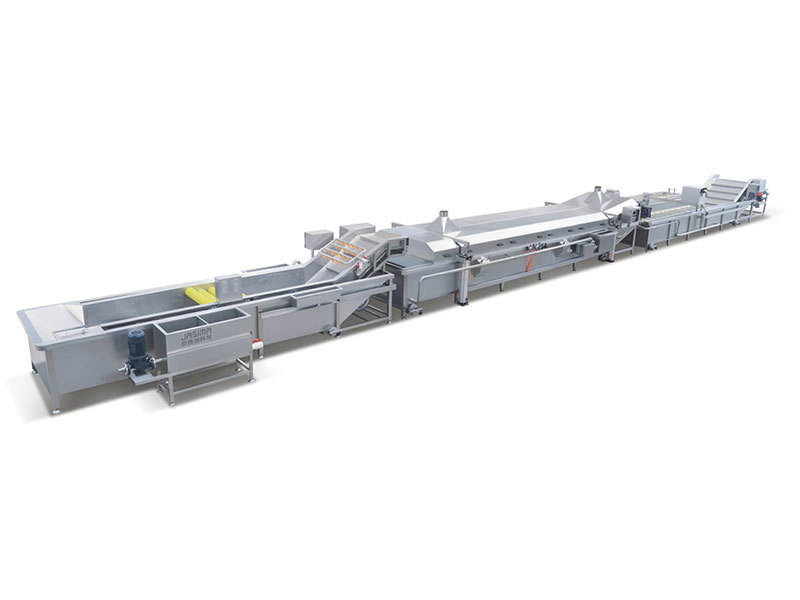

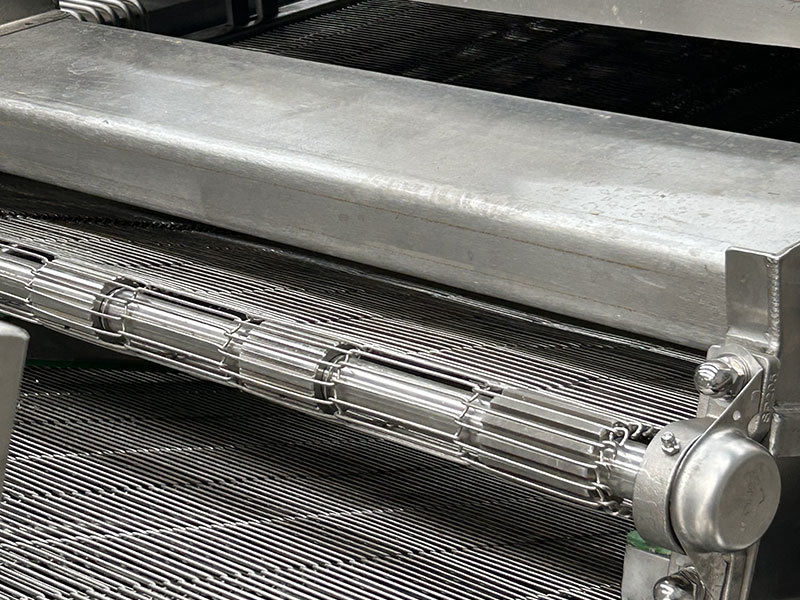

Material

The equipment is typically made from stainless steel to ensure hygiene and durability. Automation

Modern blanching lines often feature automated controls for temperature, timing, and conveyor speed, ensuring consistent quality and reducing labor costs.

Blanching line

Still deciding? Get samples first, Contact US !

- Details

-

Product Description

A blanching line is an essential piece of equipment in the food processing industry, particularly for vegetables and fruits. The primary purpose of blanching is to inactivate enzymes that can cause spoilage, to clean the product, and to prepare it for further processing such as freezing or canning. The blanching process typically involves briefly heating the product in hot water or steam, followed by rapid cooling.Product Parameters

Capacity

Blanching lines can vary significantly in capacity, ranging from small-scale units processing a few hundred kilograms per hour to large industrial lines capable of handling several tons per hour.

Temperature Control

Precise temperature control is crucial, with typical blanching temperatures ranging from 70°C to 100°C (158°F to 212°F).

Heating Medium

Options include hot water or steam, with steam being more energy-efficient and faster.

Cooling System

After blanching, the product is usually cooled using cold water or air to halt the cooking process.

Material

The equipment is typically made from stainless steel to ensure hygiene and durability. Automation

Modern blanching lines often feature automated controls for temperature, timing, and conveyor speed, ensuring consistent quality and reducing labor costs.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!