Category

Share to

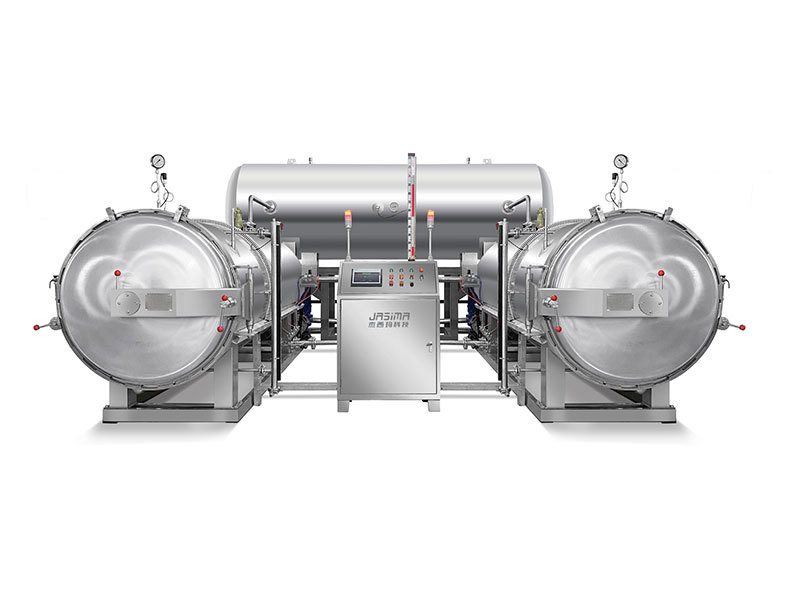

DOUBLE WATER-BATH TYPE RETORT

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

Introduction

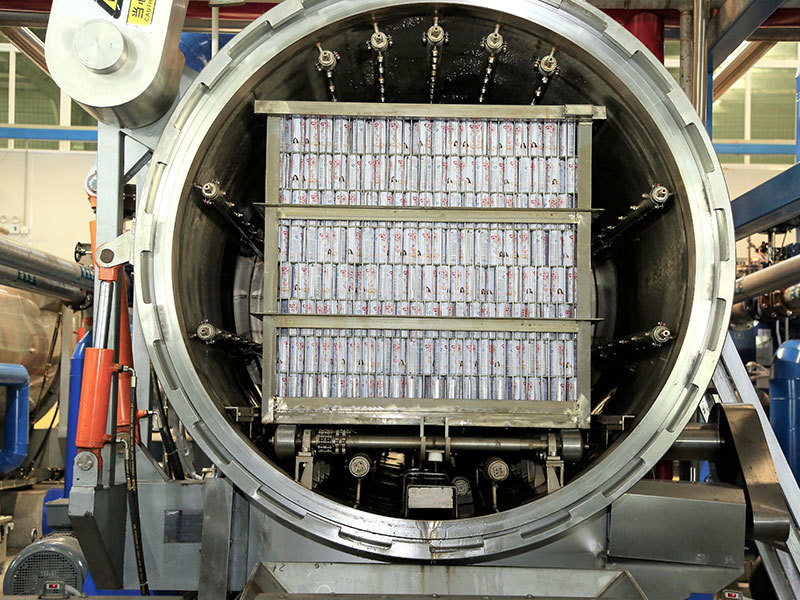

High-Temperature Sterilization Machine: This equipment is used for sterilizing products at high temperatures, ensuring they are free from harmful microorganisms. It is commonly used in the food and beverage industry to maintain product safety and extend shelf life.Pasteurization Machine: This machine uses the pasteurization process to heat and cool products, such as milk and juices, to eliminate pathogens while preserving flavor and nutritional value.

Capacity: The volume of the retort chamber, typically measured in liters or cubic meters, determines how much product can be sterilized in one batch.

Temperature Range: The operating temperature range, usually between 100°C to 140°C, is crucial for effective sterilization.

Pressure Range: The pressure inside the retort, often ranging from 1 to 3 bar, ensures proper sterilization conditions, especially for canned or packaged goods.

Heating Medium: Common heating mediums include steam, hot water, or a combination of both, which are used to achieve the required sterilization temperature.

Cooling System: Integrated cooling systems, often using water, help rapidly cool the products after sterilization to maintain quality and prevent overcooking.

Control System: Advanced PLC (Programmable Logic Controller) systems for precise control and monitoring of temperature, pressure, and sterilization time.

DOUBLE WATER-BATH TYPE RETORT

Still deciding? Get samples first, Contact US !

- Details

-

Introduction

High-Temperature Sterilization Machine: This equipment is used for sterilizing products at high temperatures, ensuring they are free from harmful microorganisms. It is commonly used in the food and beverage industry to maintain product safety and extend shelf life.Pasteurization Machine: This machine uses the pasteurization process to heat and cool products, such as milk and juices, to eliminate pathogens while preserving flavor and nutritional value.

Capacity: The volume of the retort chamber, typically measured in liters or cubic meters, determines how much product can be sterilized in one batch.

Temperature Range: The operating temperature range, usually between 100°C to 140°C, is crucial for effective sterilization.

Pressure Range: The pressure inside the retort, often ranging from 1 to 3 bar, ensures proper sterilization conditions, especially for canned or packaged goods.

Heating Medium: Common heating mediums include steam, hot water, or a combination of both, which are used to achieve the required sterilization temperature.

Cooling System: Integrated cooling systems, often using water, help rapidly cool the products after sterilization to maintain quality and prevent overcooking.

Control System: Advanced PLC (Programmable Logic Controller) systems for precise control and monitoring of temperature, pressure, and sterilization time.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!