Category

Share to

French Fries Frying Produciton Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

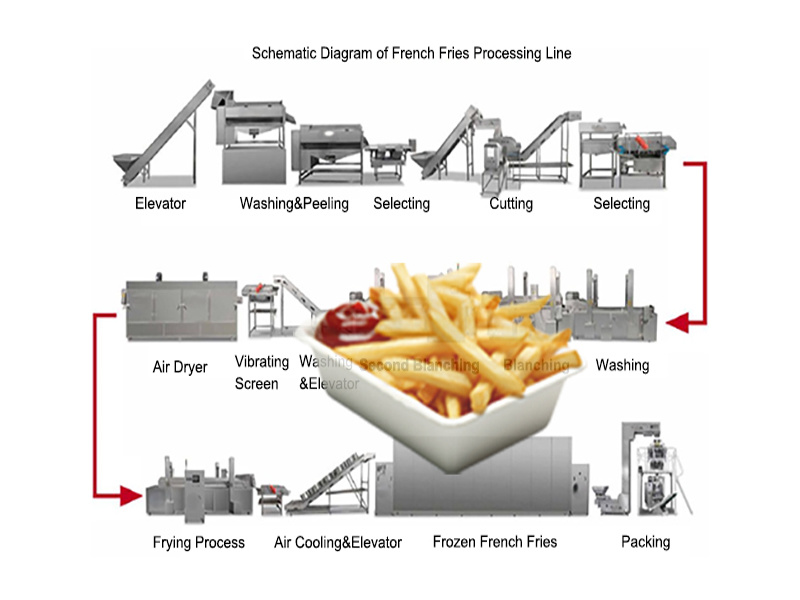

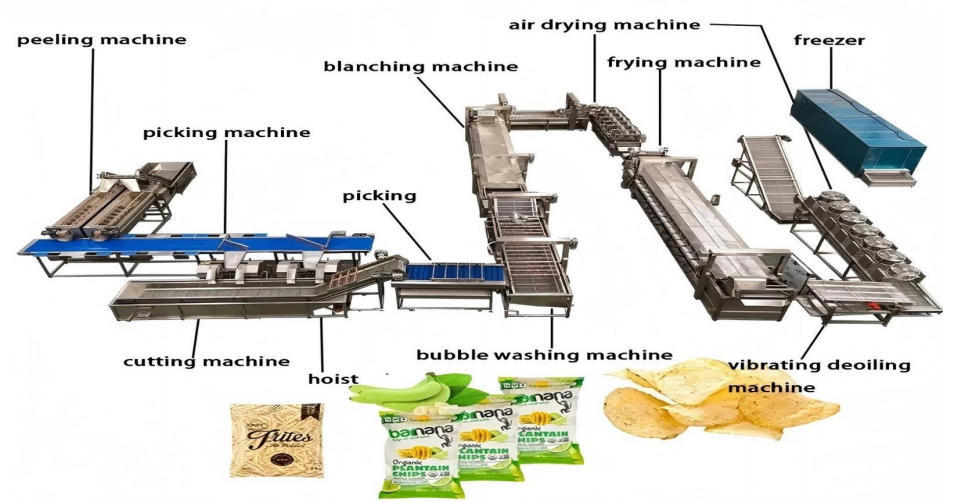

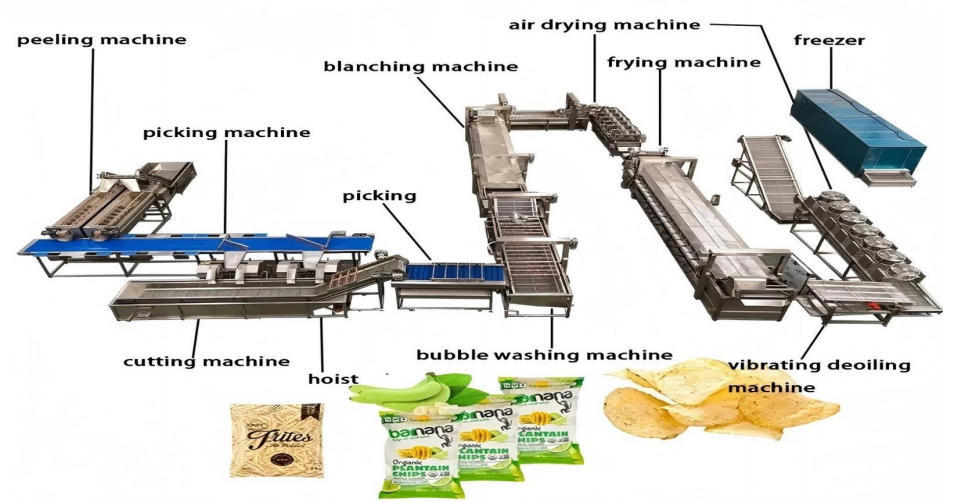

French Fries Production Line Introduction

Fresh Fries Production Line is a complete automatic production line designed for making fresh fried potato fries, generally speaking,which is consist of potato washing and peeling system, potota slicing and water flushing system, continuous deep oil frying system, drop oil and flavoring system. By absorbing advanced technology from both domestic and foreign countries, this production line is designed with extraordinary feature and good automatic performance.

Specific Process for French Fries Production

1.Sediment Lifting Machine

Sediment lifting machine is designed for conveying materials to the rough roller peeling washing machine. It features a water pool where materials can fall directly into the waterduring feeding, ensuring they are not damaged and enter the washing machine uniformlyand gently.

The frame is made of SUS304 stainless steel, and the conveyor belt is made of304 stainless steel mesh. Sand and gravel can sink beneath the conveyor belt and be discharged through a large square sewage outlet at the bottom, ensuring safety, reliability,and environmental friendliness. The conveyor operates smoothly with adjustable speed, and the material moves along the conveyor belt, preventing damage to the conveyeditems. It produces minimal noise, making it ideal for quiet environments. The system includes partition scrapers to prevent material from failing to move, ensuring uniform entry into the next process, preventing material accumulation, and reducing the workload of workers. The design is simple and easy to maintain. It has low energy consumption and low operating costs. The speed reduction motor is installed at a high position and equipped with a waterproof cover to prevent water from entering and affecting the normal operation ofthe equipment.Size Mesh Belt Width Power Material 1500*500mm 500mm 1.5kw SUS304 2.Potatp Cleaning and Peeing Machine

The potato peeling and cleaning machine, developed by our company based on the characteristics of root tuber processing machinery from both domestic and internationalsources, uses the principle of brush friction to clean and peel potatoes. The process is streamlined into a production line, with potatoes being peeled and cleaned simultaneously as they are discharged. To achieve optimal peeling results, the machine features nine rollers, two of which are diamond sand rollers.

Overall Dimension Total Power 1900*850*1100mm1.5kw 3.Elevator

Elevators are mechanical equipment that transport by changing the potential energy, with large conveying capacity and long transportation distance, and are widely used. The products from the previous process can be transported to the next process.

Length Mesh Belt Width Power 1500mm 500mm 1.5kw 4. Manual Selection Line

After the potatoes are peeled,the next process is manual selection line The manual inspection is conducted to check for any damaged or unqualified potatoes, as well as any uncleaned skins, and any necessary adjustments are made. This sorting line uses high-quality PVC food-grade conveyor belts, ensuring safety and hygiene, and meeting food standards. The conveyor belt is made of 304 high-quality stainless steel, and the motor is a speed-adjustable motor. The conveyor belt speed can be adjusted, and the machine has adjustable feet and height settings. A material distribution baffle ensures that the potatoes are evenly distributed to six cutting machines

Overall Dimension Mesh Belt Width Power Mesh Belt Material 2000*1300*800mm 400mm 0.55kw Food Grade PVC

5. French Fries Slicer

Qualified potatoes are sorted and then lifted by a conveyor to the potato slicer, a cutting equipment that continuously performs the cutting process. The blades are made of high-speed stainless steel, the turntable is made of high-quality aluminum-magnesium alloy, and the other components are 304 stainless steel, with a thickness of 2mm. The finished product has a smooth surface without damaging the tissue, making it ideal for further processing. The cutting performance is stable and efficient.

Overall Dimension Cutting Size Power 1100*800*900mm 6-15mm 0.75kw 6.Elevator

After cutting potatos into slices, they are processed by the elevator and then transported to the next process for processing.

7. Scrap Material Removal Machine

After the French fries are cut, they are lifted onto the impurity removal machine. By adjusting the distance between the rollers, the French fries move forward under the rollers, while the corners and defective French fries fall through the gaps. A collection box is placed below to collect the defective items, effectively achieving the screening process. The rollers are made of high-quality nylon wire, which meets food safety standards and has a long service life.

Size Rubber Roller Power 2000*1000mm 800mm 2.2kw 8.. Bubble pre-washing Machine

After slicing/slicing French fries, the surface starch needs to be cleaned. The buble washing machine is made of food grade materials, which are safe, reliable, and pollution-free. Low noise, suitable for work environments that require quietness. The structure is simple and easy to maintain. Low energy consumption and low usage cost. This machine is made of stainless steel material and uses water as the medium to form bubbles through a strong flow turbine fan for flexible cleaning of materials. It is made of stainless steel materials, except for standard components such as motors and bearings, which fully comply with the hygiene requirements for exported food. The equipment is equipped with a bubble generation device to make the material roll and remove starch and impurities on the surface ofthe product. It has the characteristics of high cleanliness, energy saving, water saving, and stable and reliable equipment.Overall Dimension Mesh Belt Width Power Mesh Belt Material 3000*1300*1100mm500mm 1.5kw Food Grade SUS 304 9.Blanching and Color Protection Machine

Blanching and Color Protection Machine is suitable for blanching and withering various vegetables and fruits, and is an indispensable blanching equipment for quick freezing, dehydration, freeze-drying, peeling, and other deep processing pretreatment. Compared with low labor intensity, less manpower, high degree of self-control, automatic temperature regulation within 98 C, small temperature difference between upper and lower layers, and easy control of product quality, it is an ideal equipment for the vegetable and food processing industry.

10.Vibration Drainage Machine

This machine is made of high-quality stainless steel, and the equipment mainly uses the principle of vibration motor to excite the material, so that it is thrown up on the screen surface and moves forward in a straight line to match the screen mesh reasonably, thus achieving the purpose of screening. This machine consists of a base, a vibration chamber, a vibration motor, a shock absorber, etc. The machine has smooth vibration, extremely low noise, simple operation, and excellent screening performance. It is widely used in the screening of pills and granular materials in industries such as medicine, food, and chemical.

11. Flip dryer

This drying line is designed for the pre-frying of French fries. It features a variable frequency speed motor and a flip conveyor belt that automatically flips the material during transport. The principle of operation involves conveying the blanched material through the conveyor belt, where it undergoes multiple flips to ensure uniform exposure to the wind from all sides. High-pressure air from the blowers dries the water offthe material's surface.

12.High Temperature Frying Machine

The frying machine uses a pure oil frying process and is equipped with a dynamic bottom scraping and filtering system, featuring a circulation device. During operation, it automatically filters and discharges slag, ensuring the quality of the fried oil. It uses a double-net belt conveyor to transport the French fries, preventing them from floating and frying unevenly due to being too light. The upper and lower net belts can be adjusted at variable frequencies.

13.Vibration Oil Dispenser

The material is conveyed to the vibrating oil separator via a conveyor belt, where high-frequency vibrations remove excess oil from the surface. High-quality 304 stainless steel square tubes are used, with a thickened crossbeam in the middle to ensure stability. The screening surface is designed with bent holes, facilitating material movement without causing damage. A water collection tray at the bottom facilitates the unified recovery and treatment of water that is shaken off.

14.Flip air-cooling Machine

Because the temperature of French fries is too high after frying, it consumes too much energy to go directly into the freezer, and affects the service life of the compressor. Therefore, a specially equipped air cooling line is provided.

15. Vibration Paver

The material is conveyed to the vibrating feeder by a hoist. The high-frequency vibration removes surface moisture and ensures uniform distribution to the fluidized rapid freezing machine.

16.Tunnel Type Quick Freezer

The tunnel freezer is a continuous freezing device widely used in the food processing industry. After being fried, the fries are air-cooled and then quickly frozen to maintain their good taste.

17.Packing Steps.According to different packing style, we can provide different packing machineis, the most are vacuum packing machines.

- Details

-

French Fries Production Line Introduction

Fresh Fries Production Line is a complete automatic production line designed for making fresh fried potato fries, generally speaking,which is consist of potato washing and peeling system, potota slicing and water flushing system, continuous deep oil frying system, drop oil and flavoring system. By absorbing advanced technology from both domestic and foreign countries, this production line is designed with extraordinary feature and good automatic performance.

Specific Process for French Fries Production

1.Sediment Lifting Machine

Sediment lifting machine is designed for conveying materials to the rough roller peeling washing machine. It features a water pool where materials can fall directly into the waterduring feeding, ensuring they are not damaged and enter the washing machine uniformlyand gently.

The frame is made of SUS304 stainless steel, and the conveyor belt is made of304 stainless steel mesh. Sand and gravel can sink beneath the conveyor belt and be discharged through a large square sewage outlet at the bottom, ensuring safety, reliability,and environmental friendliness. The conveyor operates smoothly with adjustable speed, and the material moves along the conveyor belt, preventing damage to the conveyeditems. It produces minimal noise, making it ideal for quiet environments. The system includes partition scrapers to prevent material from failing to move, ensuring uniform entry into the next process, preventing material accumulation, and reducing the workload of workers. The design is simple and easy to maintain. It has low energy consumption and low operating costs. The speed reduction motor is installed at a high position and equipped with a waterproof cover to prevent water from entering and affecting the normal operation ofthe equipment.Size Mesh Belt Width Power Material 1500*500mm 500mm 1.5kw SUS304 2.Potatp Cleaning and Peeing Machine

The potato peeling and cleaning machine, developed by our company based on the characteristics of root tuber processing machinery from both domestic and internationalsources, uses the principle of brush friction to clean and peel potatoes. The process is streamlined into a production line, with potatoes being peeled and cleaned simultaneously as they are discharged. To achieve optimal peeling results, the machine features nine rollers, two of which are diamond sand rollers.

Overall Dimension Total Power 1900*850*1100mm1.5kw 3.Elevator

Elevators are mechanical equipment that transport by changing the potential energy, with large conveying capacity and long transportation distance, and are widely used. The products from the previous process can be transported to the next process.

Length Mesh Belt Width Power 1500mm 500mm 1.5kw 4. Manual Selection Line

After the potatoes are peeled,the next process is manual selection line The manual inspection is conducted to check for any damaged or unqualified potatoes, as well as any uncleaned skins, and any necessary adjustments are made. This sorting line uses high-quality PVC food-grade conveyor belts, ensuring safety and hygiene, and meeting food standards. The conveyor belt is made of 304 high-quality stainless steel, and the motor is a speed-adjustable motor. The conveyor belt speed can be adjusted, and the machine has adjustable feet and height settings. A material distribution baffle ensures that the potatoes are evenly distributed to six cutting machines

Overall Dimension Mesh Belt Width Power Mesh Belt Material 2000*1300*800mm 400mm 0.55kw Food Grade PVC

5. French Fries Slicer

Qualified potatoes are sorted and then lifted by a conveyor to the potato slicer, a cutting equipment that continuously performs the cutting process. The blades are made of high-speed stainless steel, the turntable is made of high-quality aluminum-magnesium alloy, and the other components are 304 stainless steel, with a thickness of 2mm. The finished product has a smooth surface without damaging the tissue, making it ideal for further processing. The cutting performance is stable and efficient.

Overall Dimension Cutting Size Power 1100*800*900mm 6-15mm 0.75kw 6.Elevator

After cutting potatos into slices, they are processed by the elevator and then transported to the next process for processing.

7. Scrap Material Removal Machine

After the French fries are cut, they are lifted onto the impurity removal machine. By adjusting the distance between the rollers, the French fries move forward under the rollers, while the corners and defective French fries fall through the gaps. A collection box is placed below to collect the defective items, effectively achieving the screening process. The rollers are made of high-quality nylon wire, which meets food safety standards and has a long service life.

Size Rubber Roller Power 2000*1000mm 800mm 2.2kw 8.. Bubble pre-washing Machine

After slicing/slicing French fries, the surface starch needs to be cleaned. The buble washing machine is made of food grade materials, which are safe, reliable, and pollution-free. Low noise, suitable for work environments that require quietness. The structure is simple and easy to maintain. Low energy consumption and low usage cost. This machine is made of stainless steel material and uses water as the medium to form bubbles through a strong flow turbine fan for flexible cleaning of materials. It is made of stainless steel materials, except for standard components such as motors and bearings, which fully comply with the hygiene requirements for exported food. The equipment is equipped with a bubble generation device to make the material roll and remove starch and impurities on the surface ofthe product. It has the characteristics of high cleanliness, energy saving, water saving, and stable and reliable equipment.Overall Dimension Mesh Belt Width Power Mesh Belt Material 3000*1300*1100mm500mm 1.5kw Food Grade SUS 304 9.Blanching and Color Protection Machine

Blanching and Color Protection Machine is suitable for blanching and withering various vegetables and fruits, and is an indispensable blanching equipment for quick freezing, dehydration, freeze-drying, peeling, and other deep processing pretreatment. Compared with low labor intensity, less manpower, high degree of self-control, automatic temperature regulation within 98 C, small temperature difference between upper and lower layers, and easy control of product quality, it is an ideal equipment for the vegetable and food processing industry.

10.Vibration Drainage Machine

This machine is made of high-quality stainless steel, and the equipment mainly uses the principle of vibration motor to excite the material, so that it is thrown up on the screen surface and moves forward in a straight line to match the screen mesh reasonably, thus achieving the purpose of screening. This machine consists of a base, a vibration chamber, a vibration motor, a shock absorber, etc. The machine has smooth vibration, extremely low noise, simple operation, and excellent screening performance. It is widely used in the screening of pills and granular materials in industries such as medicine, food, and chemical.

11. Flip dryer

This drying line is designed for the pre-frying of French fries. It features a variable frequency speed motor and a flip conveyor belt that automatically flips the material during transport. The principle of operation involves conveying the blanched material through the conveyor belt, where it undergoes multiple flips to ensure uniform exposure to the wind from all sides. High-pressure air from the blowers dries the water offthe material's surface.

12.High Temperature Frying Machine

The frying machine uses a pure oil frying process and is equipped with a dynamic bottom scraping and filtering system, featuring a circulation device. During operation, it automatically filters and discharges slag, ensuring the quality of the fried oil. It uses a double-net belt conveyor to transport the French fries, preventing them from floating and frying unevenly due to being too light. The upper and lower net belts can be adjusted at variable frequencies.

13.Vibration Oil Dispenser

The material is conveyed to the vibrating oil separator via a conveyor belt, where high-frequency vibrations remove excess oil from the surface. High-quality 304 stainless steel square tubes are used, with a thickened crossbeam in the middle to ensure stability. The screening surface is designed with bent holes, facilitating material movement without causing damage. A water collection tray at the bottom facilitates the unified recovery and treatment of water that is shaken off.

14.Flip air-cooling Machine

Because the temperature of French fries is too high after frying, it consumes too much energy to go directly into the freezer, and affects the service life of the compressor. Therefore, a specially equipped air cooling line is provided.

15. Vibration Paver

The material is conveyed to the vibrating feeder by a hoist. The high-frequency vibration removes surface moisture and ensures uniform distribution to the fluidized rapid freezing machine.

16.Tunnel Type Quick Freezer

The tunnel freezer is a continuous freezing device widely used in the food processing industry. After being fried, the fries are air-cooled and then quickly frozen to maintain their good taste.

17.Packing Steps.According to different packing style, we can provide different packing machineis, the most are vacuum packing machines.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!