Category

Share to

Small Burger Patty Production Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

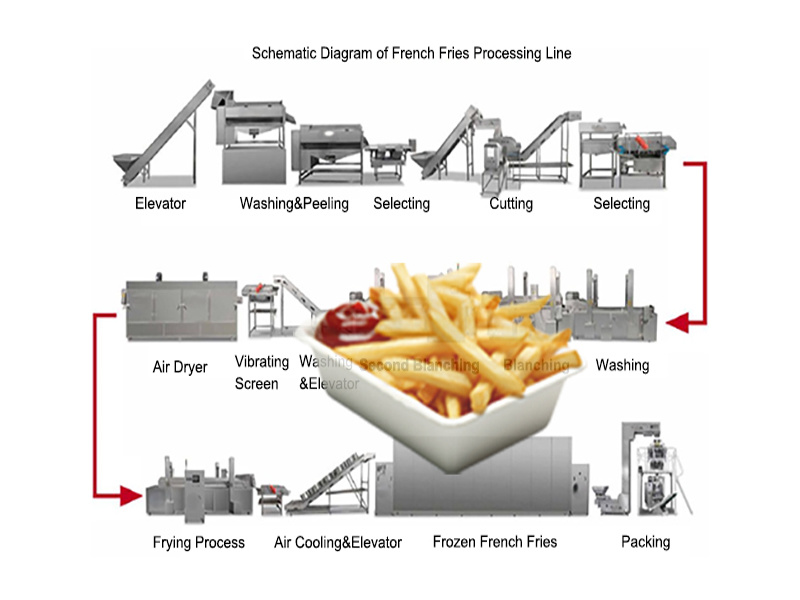

The small hamburger production line is an automated assembly line designed specifically for small-scale production, which achieves continuous processing of hamburgers from raw materials to finished products through customized equipment.It can automatically complete the process of forming hamburger patty, patty battering and hanburger breadcrumbs. The production line has high degree of automation, simple operation, convenient cleaning and meets food safety requirements.

Burger Patty Production Line Introduction

This automatic hamburger patty forming machine can automatically complete the process of forming meat patty, patty predusting, battering and breadcrumbs. It is high degree of automation, simple operation, convenient cleaning and meets food safety requirements.

Automatic burger patty forming machine can automatically perform various procedures such as meat filling, forming and output .Endless patterns can design for fabulous meat food products: circle, square, ellipse, triangle, heart and some other patterns .

According to the forming machine drive structure and forming principle, Specifications, sizes and shapes of molding products can be met by replacing different molds.

The product is placed on the conveyor belt, the conveyor belt carries the product slowly through the slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity.

The humburger patty is placed on the conveyor belt, the conveyor belt carries the product slowly through the battering machine's slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity.

The Battering Machine Made of food grade SUS304 stainless steel (including screws, nuts and other components), long-term use does not rust, does not corrode.

The slurry machine consists of two layers of conveyor belt, slurry groove, wind knife and other structures, suitable for slurry of different thickness and viscosity.

Up and down mesh band gap can be adjusted, suitable for the impregnation process of multi-specification products.

The hamburger breading machine is a pretreatment equipment inthe processing of fried products. lts function is to evenly wrap theproducts with a layer of bread crumbs, protect the fried products.and increase the coior and flavor of the products. lt is anindispensable equipment in the processing of fried products. The breading machine can be used together with the battering machine or can be used alone. It can be used to treat the topcrumbs of popular hamburger patties, McNuggets, fish flavoredhamburger patties, potato cakes, pumpkin cakes, meat kebabs andother products in the market It is an ideal top crumb equipment forfast food restaurants, distribution centers and food factories.

Automatic frying machine adopts oll-water mixed filter residue structure system, frequency conversionspeed regulation, large frying output and high production eficiency. With unique product conveying system, discharging system, heating system, oil circulation system, smoke exhaust system and electric controlsystem can be sultable for varlous energy sources and meet the different requlrements of users.

Our continous frying machine can be used for many products, such as nuts , broad beans, green beans and peanuts;puffed foods such as fried rice sticks, potato chips,etc.Flour products such as glutinous rice sticks, cat's ears, SaQima and Mahua.Meat products such as humber patties and chicken nuggets; Aquatic products such as fish nugget,cod fillet, squid ring and so on.

Burger Patty Production Line Product Name Overall Dimension Power Forming Machine 860*600*1400mm 0.55kw Battering Machine 1400*760*680mm 1kw Breading Machine 1700*680*1500mm 1.1kw Frying Machine

3500*1700*2100mm 1.5KW(Oil Pump)

FAQ

1.How to confirm the order?

Firstly, you need to confirm your patty size /thickness and your capacity.We need to make a mold for the patty formig machine.This step is very important.

Secondly, if you have your own produciton process, you can tell us.if not,we can make the production line accoring to our experience.

Finally, confirm some details,such as all the machine's voltage you need, for example, we are 380v,3 phase and 50HZ.If you need frying machine, you can also confirm it's heating. For example, electric or gas .

2.What is the delivery time for this small burger patty production line?

Generally, our delivery time will be within 20 working days after receiving the deposit. Of course, we will confirm with each customers before placing the PO.

3.Do you provide installation services overseas?

Yes,we can provide this service if customer requires .At the same time, we will charge relevant installation fees

Small Burger Patty Production Line

Still deciding? Get samples first, Contact US !

- Details

-

The small hamburger production line is an automated assembly line designed specifically for small-scale production, which achieves continuous processing of hamburgers from raw materials to finished products through customized equipment.It can automatically complete the process of forming hamburger patty, patty battering and hanburger breadcrumbs. The production line has high degree of automation, simple operation, convenient cleaning and meets food safety requirements.

Burger Patty Production Line Introduction

This automatic hamburger patty forming machine can automatically complete the process of forming meat patty, patty predusting, battering and breadcrumbs. It is high degree of automation, simple operation, convenient cleaning and meets food safety requirements.

Automatic burger patty forming machine can automatically perform various procedures such as meat filling, forming and output .Endless patterns can design for fabulous meat food products: circle, square, ellipse, triangle, heart and some other patterns .

According to the forming machine drive structure and forming principle, Specifications, sizes and shapes of molding products can be met by replacing different molds.

The product is placed on the conveyor belt, the conveyor belt carries the product slowly through the slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity.

The humburger patty is placed on the conveyor belt, the conveyor belt carries the product slowly through the battering machine's slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity.

The Battering Machine Made of food grade SUS304 stainless steel (including screws, nuts and other components), long-term use does not rust, does not corrode.

The slurry machine consists of two layers of conveyor belt, slurry groove, wind knife and other structures, suitable for slurry of different thickness and viscosity.

Up and down mesh band gap can be adjusted, suitable for the impregnation process of multi-specification products.

The hamburger breading machine is a pretreatment equipment inthe processing of fried products. lts function is to evenly wrap theproducts with a layer of bread crumbs, protect the fried products.and increase the coior and flavor of the products. lt is anindispensable equipment in the processing of fried products. The breading machine can be used together with the battering machine or can be used alone. It can be used to treat the topcrumbs of popular hamburger patties, McNuggets, fish flavoredhamburger patties, potato cakes, pumpkin cakes, meat kebabs andother products in the market It is an ideal top crumb equipment forfast food restaurants, distribution centers and food factories.

Automatic frying machine adopts oll-water mixed filter residue structure system, frequency conversionspeed regulation, large frying output and high production eficiency. With unique product conveying system, discharging system, heating system, oil circulation system, smoke exhaust system and electric controlsystem can be sultable for varlous energy sources and meet the different requlrements of users.

Our continous frying machine can be used for many products, such as nuts , broad beans, green beans and peanuts;puffed foods such as fried rice sticks, potato chips,etc.Flour products such as glutinous rice sticks, cat's ears, SaQima and Mahua.Meat products such as humber patties and chicken nuggets; Aquatic products such as fish nugget,cod fillet, squid ring and so on.

Burger Patty Production Line Product Name Overall Dimension Power Forming Machine 860*600*1400mm 0.55kw Battering Machine 1400*760*680mm 1kw Breading Machine 1700*680*1500mm 1.1kw Frying Machine

3500*1700*2100mm 1.5KW(Oil Pump)

FAQ

1.How to confirm the order?

Firstly, you need to confirm your patty size /thickness and your capacity.We need to make a mold for the patty formig machine.This step is very important.

Secondly, if you have your own produciton process, you can tell us.if not,we can make the production line accoring to our experience.

Finally, confirm some details,such as all the machine's voltage you need, for example, we are 380v,3 phase and 50HZ.If you need frying machine, you can also confirm it's heating. For example, electric or gas .

2.What is the delivery time for this small burger patty production line?

Generally, our delivery time will be within 20 working days after receiving the deposit. Of course, we will confirm with each customers before placing the PO.

3.Do you provide installation services overseas?

Yes,we can provide this service if customer requires .At the same time, we will charge relevant installation fees

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!