Forming Machine

Category

Share to

Chicken Nuggets Machine for Nugget Production

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

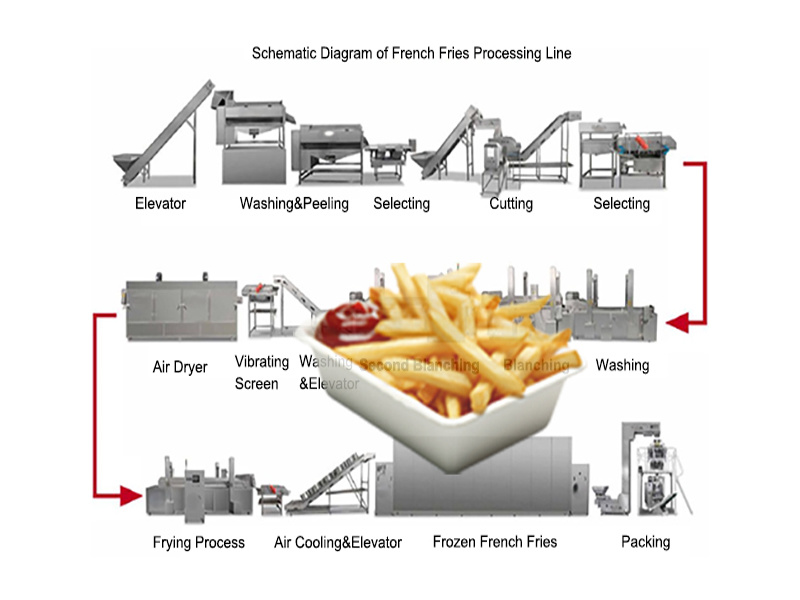

What is the Chicken Nugget Production Process?How to make Chicken Nugget?

Generally, fully automatic chicken nuggets machine includes a series of nugget processing machines.For example, nuggets forming machine,nugget battering, flouring (pre-dusting), breading, frying, etc. We can provide a complete chicken nugget produciton line accoring to your actual situation once you can confirm the nugget size.

Chicken Nuggets Machine Introduction

1.Chicken Nugget Automatic Forming Machine

Automatial chicken nuggets forming machine is made of food grade SUS304 stainless steel (including screws, nuts, and other components), it does not rust or corrode after long-term use.By simply changing different molds, products with different shapes (circular, square, elliptical, triangular, heart-shaped, and other special shapes) can be produced.

Apart from Chicken Nuggets,the forming machine can be also used to make hamburger patties, fish and shrimp patties, potato , vegetable cakes, pumpkin patties and other foods.The following is basic parameter of this machine.

2.Chicken Nuggets Battering Machine

Battering machine is also made of food grade SUS304 stainless steel and it includes two layers of conveyor belts, a slurry tank, a wind knife, and other structures.It's suitable for slurries of different thicknesses and viscosities. The gap between the upper and lower mesh belts can be adjusted, suitable for the soaking process of multi specification products.

3.Chicken Nuggets Breading Machine

The breading machine can automatically completes the process of wrapping the product with bran, including fine bran, coarse bran, and snowflakes. The product after battering enters the lower mesh belt, and the bottom and sides are covered with breadcrumbs. The breadcrumbs flowing down from the upper hopper cover the upper part of the product, and after being pressed by the pressure roller (the thickness of the breadcrumbs on the upper and lower mesh belts can be easily adjusted), the breadcrumbs can be fully wrapped around the product.After wrapping the crumbs on top, the excess crumbs are blown off by air shower, and multiple parts can be adjusted to effectively control the amount of bran.

4..Chicken Nuggets Frying Machine

Automatically frying machine is suitalbe for chicken nugget frying because it can achieve continuous frying and control the temperature accurately.Adopting a tunnel type chain driven stainless steel mesh belt conveyor, the frying time of the product can be effectively controlled during the frying process.

Chicken Nuggets Machine Photos Display and Parameters

Product Name Over Dimension Total Power Capacity Forming Machine 860*600*1400mm

0.55kw 35pcs/min(based on the product) Battering Machine 1400*760*680mm 1kw 200kg/h Breading Machine 1700*680*1500mm 1.1kw 200kg/h Frying Machine 3500*1700*2100mm / / After frying the chicken chunks, an air cooling line is necessary.The air-cooled conveyor belt adopts 304 stainless steel mesh belt. Three high-power axial flow fans, whose working principle is to transport fried products into the air, use strong wind to blow off excess oil on the surface of the products and cool them down. The height of the fan can be adjusted. There is an oil pan at the bottom of the machine, and the drained oil is collected and discharged uniformly.

- Details

-

What is the Chicken Nugget Production Process?How to make Chicken Nugget?

Generally, fully automatic chicken nuggets machine includes a series of nugget processing machines.For example, nuggets forming machine,nugget battering, flouring (pre-dusting), breading, frying, etc. We can provide a complete chicken nugget produciton line accoring to your actual situation once you can confirm the nugget size.

Chicken Nuggets Machine Introduction

1.Chicken Nugget Automatic Forming Machine

Automatial chicken nuggets forming machine is made of food grade SUS304 stainless steel (including screws, nuts, and other components), it does not rust or corrode after long-term use.By simply changing different molds, products with different shapes (circular, square, elliptical, triangular, heart-shaped, and other special shapes) can be produced.

Apart from Chicken Nuggets,the forming machine can be also used to make hamburger patties, fish and shrimp patties, potato , vegetable cakes, pumpkin patties and other foods.The following is basic parameter of this machine.

2.Chicken Nuggets Battering Machine

Battering machine is also made of food grade SUS304 stainless steel and it includes two layers of conveyor belts, a slurry tank, a wind knife, and other structures.It's suitable for slurries of different thicknesses and viscosities. The gap between the upper and lower mesh belts can be adjusted, suitable for the soaking process of multi specification products.

3.Chicken Nuggets Breading Machine

The breading machine can automatically completes the process of wrapping the product with bran, including fine bran, coarse bran, and snowflakes. The product after battering enters the lower mesh belt, and the bottom and sides are covered with breadcrumbs. The breadcrumbs flowing down from the upper hopper cover the upper part of the product, and after being pressed by the pressure roller (the thickness of the breadcrumbs on the upper and lower mesh belts can be easily adjusted), the breadcrumbs can be fully wrapped around the product.After wrapping the crumbs on top, the excess crumbs are blown off by air shower, and multiple parts can be adjusted to effectively control the amount of bran.

4..Chicken Nuggets Frying Machine

Automatically frying machine is suitalbe for chicken nugget frying because it can achieve continuous frying and control the temperature accurately.Adopting a tunnel type chain driven stainless steel mesh belt conveyor, the frying time of the product can be effectively controlled during the frying process.

Chicken Nuggets Machine Photos Display and Parameters

Product Name Over Dimension Total Power Capacity Forming Machine 860*600*1400mm

0.55kw 35pcs/min(based on the product) Battering Machine 1400*760*680mm 1kw 200kg/h Breading Machine 1700*680*1500mm 1.1kw 200kg/h Frying Machine 3500*1700*2100mm / / After frying the chicken chunks, an air cooling line is necessary.The air-cooled conveyor belt adopts 304 stainless steel mesh belt. Three high-power axial flow fans, whose working principle is to transport fried products into the air, use strong wind to blow off excess oil on the surface of the products and cool them down. The height of the fan can be adjusted. There is an oil pan at the bottom of the machine, and the drained oil is collected and discharged uniformly.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!