Category

Share to

200kg Potato Chips Production Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

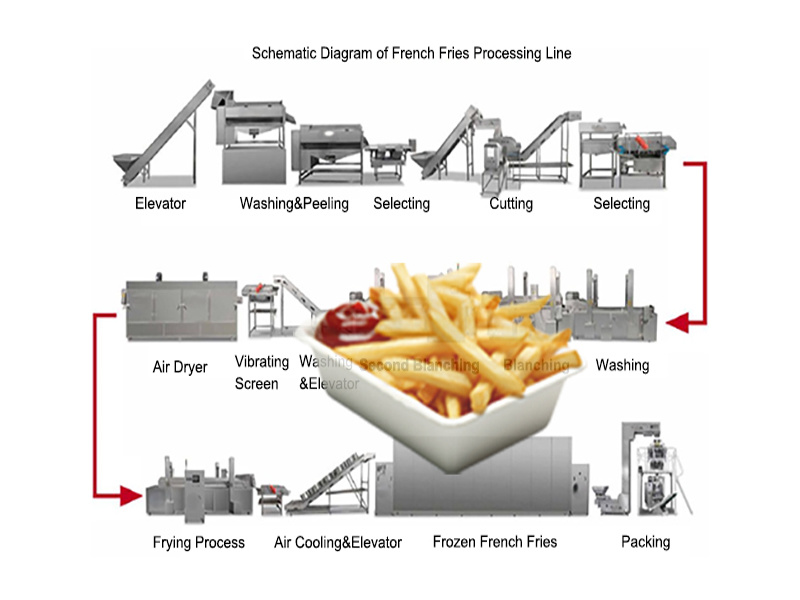

The potato chip production line is an automatic equipment system used to continuously process raw materials such as potatoes into finished potato chips, covering the entire process from raw material processing to finished product packaging. Its core goal is to efficiently and standardly produce crispy and delicious potato chips, suitable for large-scale industrial production.

Potato Chips Production Process

Firstly, improve the feeding and cleaning of peeling: Potatoes are transported to the hair roller cleaning peeling machine through a lifting machine, and the skin is removed by friction. Some processes use steam or high-pressure spraying to assist in cleaning.

Secondly, selecting pruning and slicing processing: After manually or mechanically selecting defective products, potatoes are sliced evenly into thin slices (with adjustable thickness) by a slicer to ensure consistent frying. Next, rinse and blanch to protect the color: the slices are rinsed with a bubble washer to remove starch impurities, and then color cured and improved in taste by a blanching machine. Then, dehydration and frying:

Potato chips are dehydrated on a wind powered dehydrator and then enter the frying production line. High temperature frying makes them crispy, and the equipment usually has automatic temperature control function. Afterwards, degreasing and seasoning: The fried potato chips are degreased by centrifugation or vibration, and then seasoning is evenly added to the seasoning line. Finally, cooling and packaging: After the finished product is cooled down by the cooling line, it is equally packaged by a fully automatic packaging machine and regularly filled with nitrogen to prevent crushing.

Potato Chips Making Machine's Introduction

Stone Sinking Hoist is located at the front end of the potato chip production line and used to soak, clean, remove mud and dirt from the materials, and then transport them to the continuous peeling machine for operation.

The sheet metal thickness is 3.0mm.The conveyor belt is made of food grade PP material, with a deviation correction function and a plastic baffle for placing and rolling materials. The effective width is 485mm.

It can achieve quick disassembly and easy cleaning of the entire machine.The conveying speed can be adjusted by frequency conversion, making the cooling time more accurate. The frequency converter can better protect the motor, extend its service life, and be more energy-efficient.

Continuous Brush Peeling Machine is located at the rear end of the pre soaking elevator in production line, and is used to perform brush peeling operations on materials.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 60mm * 40mm rectangular tubes with a thickness of 2.0mm. The sheet metal thickness for structural key positions is 12mm, and for other non key positions it is 1.5mm.The brush is made of food grade hard bristles with an effective length of 2300mm.

It can achieve quick disassembly and easy cleaning of the entire machine.

Conveyor speed: The speed of the winch and brush is infinitely variable

Bar Selection Machine is used to visually select materials that have been peeled in batches, and then transport them to the chain plate elevator after selection.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 50mm diameter square tubes with a thickness of 2.0mm. The sheet metal thickness is 3.0mm, and the rod diameter is 63mm with a thickness of 1.5mm.

The device is capable of rotating the entire shaft with real power, making it easy to transport materials to the next process; The individual stick can rotate on its own, making it convenient for visual inspection of material flipping.

The maximum capacity of this machine is six workstations for operation.

Conveyor speed: Conventional constant speed, optional variable speed conveyor.

Chain Eelevator is used to select qualified materials for lifting to the vegetable cutter.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 50mm diameter square tubes with a thickness of 2.0mm; the sheet metal thickness is 3.0mm.

The conveyor belt is made of food grade PP material, with a deviation correction function and a plastic baffle for placing and rolling materials. The effective width is 485mm.

It can achieve quick disassembly and easy cleaning of the entire machine.

Conveyor speed: Conventional constant speed, optional variable speed conveyor.果)

Due to uniform cutting thickness, potato chips slicer is commonly used for processing fried products such as potato chips.

Adopting a two-dimensional centrifugal cutting machine: made entirely of stainless steel, with a heavy-duty frame structure and sandblasted surface treatment.Concise design, no exposed nuts, smooth surface design, easy to clean.

The driving area and cutting area are completely separated, with high hygiene standards and easy maintenance. Rotating feeding port, equipped with a safety switch, can be connected to a feeding machine.Circular discharge port, can be adapted to the material box or discharge conveyor according to customer requirements. Equipped with stainless steel mobile casters.

Adopting German imported cutting tools, they are extremely sharp and do not require sharpening, with low replacement costs.Specification of erasable wire: 2.4mm, 3.2mm square wire.

Sliceable: 1-5mm flat and corrugated sheet

Blanching Machine is made of food grade SUS304 stainless steel, it does not rust or corrode after long-term use, has a long service life, and is not easily deformed.

The machine operates automatically throughout the entire process and can continuously feed and discharge materials. Both sides of the chain are equipped with protective devices to prevent materials from being caught in the chain and causing damage to the materials. A well-designed tensioning device can effectively adjust the tightness of the conveyor belt, preventing its looseness and deviation.

The steaming, boiling, and blanching time and temperature can be freely adjusted and controlled. The conveyor adopts variable frequency speed regulation, which can better protect the motor and more accurately control the blanching time.The bottom of the sink is seamlessly welded in a straight inclined manner, with a 6cm slope from one side to the other. The large diameter drainage outlet is beneficial for equipment drainage and thorough drainage.

Blanching machine are carried out immediately after blanching, with the aim of rapidly reducing the temperature of the French fries to lock in the structure and prevent excessive loss of moisture or softening caused by residual heat. That is the cooling machine function.

Blanched French fries should be quickly removed and soaked in cold water to ensure complete cooling before frying.

This process can enhance the crispness of French fries, especially during frozen storage, as well cooled fries are more likely to form a stable structure and have a better taste after frying.

Filp Air Dryer Machine is used for drying and removing water from potato chips before they enter the frying machine. It is made of high-quality 304 stainless steel material, with a variable frequency speed motor and a conveyor belt in the form of a flip.

The material can be automatically flipped during the conveying process. There are 12 high-power fans, each with a power of 0.75KW. The height of the fans can be adjusted. The working principle is to transport the blanched material through a conveyor belt and flip it multiple times to achieve the uniformity of the material's multi-faceted and windward effects.

The high-pressure wind of the blower is used to blow away the water on the surface of the material. The air nozzle is designed in a knife shape, effectively increasing the air pressure and blowing away the moisture on the surface of the material in a short time, which is convenient for subsequent processes.

The material is conveyed to the vibrating drain machine through a conveyor belt, and most of the surface moisture is removed through high-frequency vibration. The material is 304 stainless steel, with a plate thickness of 2mm.

The frame is made of high-quality 80 * 80 * 2mm 304 stainless steel square tubes, and there is a thickened crossbeam in the middle to ensure the stability of the equipment. The vibration motor adopts Shenzhen Putian brand, waterproof, high vibration frequency, good effect, low noise, and long service life.

The screening surface is designed with bending and punching holes, which facilitates the advancement of materials without damaging them. There is a water collection tray at the bottom, which facilitates the unified recycling and treatment of water that has been shaken off.

Potato Chips Frying Machine uses a pure oil frying process, equipped with a dynamic bottom scraper filtration system and a circulation device. During operation, it achieves automatic filtration and slag discharge to ensure the quality of fried oil.

Made entirely from high-quality 304 stainless steel, it features an automatic lifting function for easy cleaning and maintenance. It uses dual mesh belts to convey the fries, preventing them from floating due to being too light and ensuring even frying. The upper and lower mesh belts can be adjusted at variable frequencies. Additionally, it is equipped with a carbon dioxide fire extinguishing system.

This Air Cooling Machine is used for draining oil and cooling products after deep frying.The whole machine is made of 304 stainless steel, which is corrosion-resistant and rust free for long-term use, and meets food safety requirements.During operation, the entire process is automatically conveyed and can continuously feed and discharge materials.

The tensioning device is designed reasonably and can adjust the tightness of the conveyor belt to prevent it from loosening and deviating.The conveying speed can be adjusted by frequency conversion, making the cooling time more accurate. The frequency converter can better protect the motor, extend its service life, and be more energy-efficient. The height of the fan can be adjusted.

The conveyor belt adopts 304 stainless steel mesh belt. Four high-power axial flow fans, whose working principle is to transport fried products into the air, use strong wind to blow off excess oil on the surface of the products and cool them down.There is an oil pan at the bottom, and the drained oil is collected and discharged uniformly.

The Elevator is used to feed the drum mixer. The frame is made of SUS304 stainless steel, and the conveyor belt uses food-grade PVC material, ensuring safety, reliability, and no pollution. The conveyance is smooth, with adjustable speed, allowing materials to move along the belt without causing damage.

It produces minimal noise, making it suitable for quiet working environments. Equipped with zoned scrapers, it prevents material from being left behind, ensuring even distribution into the next process and preventing accumulation, thus reducing labor intensity. The structure is simple and easy to maintain. It has low energy consumption and low operating costs. The speed reduction motor is installed at a high position with a waterproof cover to prevent water ingress that could affect normal operation. The discharge port is fitted with a plug that fits tightly into the drum mixer, ensuring no material falls out.

This Drum Mixer is used for continuous mixing of materials, with a high degree of automation and forming an assembly line to save labor.

The seasoning is evenly and continuously spread into the drum by the propeller, and the material is seasoned and mixed through the rotation of the drum.

The mixing is uniform and the integrity of the material is guaranteed, which is convenient and practical.

Automatic Potato Chips Packing Machine

Packaging Process:

1. Loading.

2. Bag molding and injection.

3. Sealing and output.

200kg Potato Chips Production Line

Still deciding? Get samples first, Contact US !

- Details

-

The potato chip production line is an automatic equipment system used to continuously process raw materials such as potatoes into finished potato chips, covering the entire process from raw material processing to finished product packaging. Its core goal is to efficiently and standardly produce crispy and delicious potato chips, suitable for large-scale industrial production.

Potato Chips Production Process

Firstly, improve the feeding and cleaning of peeling: Potatoes are transported to the hair roller cleaning peeling machine through a lifting machine, and the skin is removed by friction. Some processes use steam or high-pressure spraying to assist in cleaning.

Secondly, selecting pruning and slicing processing: After manually or mechanically selecting defective products, potatoes are sliced evenly into thin slices (with adjustable thickness) by a slicer to ensure consistent frying. Next, rinse and blanch to protect the color: the slices are rinsed with a bubble washer to remove starch impurities, and then color cured and improved in taste by a blanching machine. Then, dehydration and frying:

Potato chips are dehydrated on a wind powered dehydrator and then enter the frying production line. High temperature frying makes them crispy, and the equipment usually has automatic temperature control function. Afterwards, degreasing and seasoning: The fried potato chips are degreased by centrifugation or vibration, and then seasoning is evenly added to the seasoning line. Finally, cooling and packaging: After the finished product is cooled down by the cooling line, it is equally packaged by a fully automatic packaging machine and regularly filled with nitrogen to prevent crushing.

Potato Chips Making Machine's Introduction

Stone Sinking Hoist is located at the front end of the potato chip production line and used to soak, clean, remove mud and dirt from the materials, and then transport them to the continuous peeling machine for operation.

The sheet metal thickness is 3.0mm.The conveyor belt is made of food grade PP material, with a deviation correction function and a plastic baffle for placing and rolling materials. The effective width is 485mm.

It can achieve quick disassembly and easy cleaning of the entire machine.The conveying speed can be adjusted by frequency conversion, making the cooling time more accurate. The frequency converter can better protect the motor, extend its service life, and be more energy-efficient.

Continuous Brush Peeling Machine is located at the rear end of the pre soaking elevator in production line, and is used to perform brush peeling operations on materials.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 60mm * 40mm rectangular tubes with a thickness of 2.0mm. The sheet metal thickness for structural key positions is 12mm, and for other non key positions it is 1.5mm.The brush is made of food grade hard bristles with an effective length of 2300mm.

It can achieve quick disassembly and easy cleaning of the entire machine.

Conveyor speed: The speed of the winch and brush is infinitely variable

Bar Selection Machine is used to visually select materials that have been peeled in batches, and then transport them to the chain plate elevator after selection.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 50mm diameter square tubes with a thickness of 2.0mm. The sheet metal thickness is 3.0mm, and the rod diameter is 63mm with a thickness of 1.5mm.

The device is capable of rotating the entire shaft with real power, making it easy to transport materials to the next process; The individual stick can rotate on its own, making it convenient for visual inspection of material flipping.

The maximum capacity of this machine is six workstations for operation.

Conveyor speed: Conventional constant speed, optional variable speed conveyor.

Chain Eelevator is used to select qualified materials for lifting to the vegetable cutter.

The whole machine is made of food grade 304 stainless steel, and the skeleton is made of 50mm diameter square tubes with a thickness of 2.0mm; the sheet metal thickness is 3.0mm.

The conveyor belt is made of food grade PP material, with a deviation correction function and a plastic baffle for placing and rolling materials. The effective width is 485mm.

It can achieve quick disassembly and easy cleaning of the entire machine.

Conveyor speed: Conventional constant speed, optional variable speed conveyor.果)

Due to uniform cutting thickness, potato chips slicer is commonly used for processing fried products such as potato chips.

Adopting a two-dimensional centrifugal cutting machine: made entirely of stainless steel, with a heavy-duty frame structure and sandblasted surface treatment.Concise design, no exposed nuts, smooth surface design, easy to clean.

The driving area and cutting area are completely separated, with high hygiene standards and easy maintenance. Rotating feeding port, equipped with a safety switch, can be connected to a feeding machine.Circular discharge port, can be adapted to the material box or discharge conveyor according to customer requirements. Equipped with stainless steel mobile casters.

Adopting German imported cutting tools, they are extremely sharp and do not require sharpening, with low replacement costs.Specification of erasable wire: 2.4mm, 3.2mm square wire.

Sliceable: 1-5mm flat and corrugated sheet

Blanching Machine is made of food grade SUS304 stainless steel, it does not rust or corrode after long-term use, has a long service life, and is not easily deformed.

The machine operates automatically throughout the entire process and can continuously feed and discharge materials. Both sides of the chain are equipped with protective devices to prevent materials from being caught in the chain and causing damage to the materials. A well-designed tensioning device can effectively adjust the tightness of the conveyor belt, preventing its looseness and deviation.

The steaming, boiling, and blanching time and temperature can be freely adjusted and controlled. The conveyor adopts variable frequency speed regulation, which can better protect the motor and more accurately control the blanching time.The bottom of the sink is seamlessly welded in a straight inclined manner, with a 6cm slope from one side to the other. The large diameter drainage outlet is beneficial for equipment drainage and thorough drainage.

Blanching machine are carried out immediately after blanching, with the aim of rapidly reducing the temperature of the French fries to lock in the structure and prevent excessive loss of moisture or softening caused by residual heat. That is the cooling machine function.

Blanched French fries should be quickly removed and soaked in cold water to ensure complete cooling before frying.

This process can enhance the crispness of French fries, especially during frozen storage, as well cooled fries are more likely to form a stable structure and have a better taste after frying.

Filp Air Dryer Machine is used for drying and removing water from potato chips before they enter the frying machine. It is made of high-quality 304 stainless steel material, with a variable frequency speed motor and a conveyor belt in the form of a flip.

The material can be automatically flipped during the conveying process. There are 12 high-power fans, each with a power of 0.75KW. The height of the fans can be adjusted. The working principle is to transport the blanched material through a conveyor belt and flip it multiple times to achieve the uniformity of the material's multi-faceted and windward effects.

The high-pressure wind of the blower is used to blow away the water on the surface of the material. The air nozzle is designed in a knife shape, effectively increasing the air pressure and blowing away the moisture on the surface of the material in a short time, which is convenient for subsequent processes.

The material is conveyed to the vibrating drain machine through a conveyor belt, and most of the surface moisture is removed through high-frequency vibration. The material is 304 stainless steel, with a plate thickness of 2mm.

The frame is made of high-quality 80 * 80 * 2mm 304 stainless steel square tubes, and there is a thickened crossbeam in the middle to ensure the stability of the equipment. The vibration motor adopts Shenzhen Putian brand, waterproof, high vibration frequency, good effect, low noise, and long service life.

The screening surface is designed with bending and punching holes, which facilitates the advancement of materials without damaging them. There is a water collection tray at the bottom, which facilitates the unified recycling and treatment of water that has been shaken off.

Potato Chips Frying Machine uses a pure oil frying process, equipped with a dynamic bottom scraper filtration system and a circulation device. During operation, it achieves automatic filtration and slag discharge to ensure the quality of fried oil.

Made entirely from high-quality 304 stainless steel, it features an automatic lifting function for easy cleaning and maintenance. It uses dual mesh belts to convey the fries, preventing them from floating due to being too light and ensuring even frying. The upper and lower mesh belts can be adjusted at variable frequencies. Additionally, it is equipped with a carbon dioxide fire extinguishing system.

This Air Cooling Machine is used for draining oil and cooling products after deep frying.The whole machine is made of 304 stainless steel, which is corrosion-resistant and rust free for long-term use, and meets food safety requirements.During operation, the entire process is automatically conveyed and can continuously feed and discharge materials.

The tensioning device is designed reasonably and can adjust the tightness of the conveyor belt to prevent it from loosening and deviating.The conveying speed can be adjusted by frequency conversion, making the cooling time more accurate. The frequency converter can better protect the motor, extend its service life, and be more energy-efficient. The height of the fan can be adjusted.

The conveyor belt adopts 304 stainless steel mesh belt. Four high-power axial flow fans, whose working principle is to transport fried products into the air, use strong wind to blow off excess oil on the surface of the products and cool them down.There is an oil pan at the bottom, and the drained oil is collected and discharged uniformly.

The Elevator is used to feed the drum mixer. The frame is made of SUS304 stainless steel, and the conveyor belt uses food-grade PVC material, ensuring safety, reliability, and no pollution. The conveyance is smooth, with adjustable speed, allowing materials to move along the belt without causing damage.

It produces minimal noise, making it suitable for quiet working environments. Equipped with zoned scrapers, it prevents material from being left behind, ensuring even distribution into the next process and preventing accumulation, thus reducing labor intensity. The structure is simple and easy to maintain. It has low energy consumption and low operating costs. The speed reduction motor is installed at a high position with a waterproof cover to prevent water ingress that could affect normal operation. The discharge port is fitted with a plug that fits tightly into the drum mixer, ensuring no material falls out.

This Drum Mixer is used for continuous mixing of materials, with a high degree of automation and forming an assembly line to save labor.

The seasoning is evenly and continuously spread into the drum by the propeller, and the material is seasoned and mixed through the rotation of the drum.

The mixing is uniform and the integrity of the material is guaranteed, which is convenient and practical.

Automatic Potato Chips Packing Machine

Packaging Process:

1. Loading.

2. Bag molding and injection.

3. Sealing and output.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!