Category

Share to

Tunnel Type Breading Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

Product Description

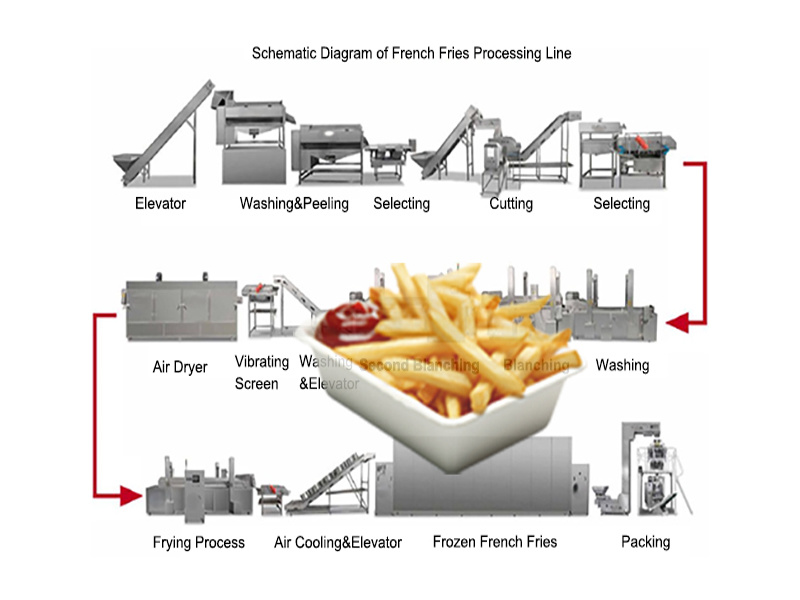

The tunnel breading machine is a pre-treatment equipment in the processing of fried products. Its function is to evenly coat the products with breadcrumbs, which protect the fried products and enhance their color and flavor. It is an indispensable equipment in the processing of fried products. The breadcrumb machine can be used in conjunction with the battering machine or independently. It can be used to breadcrumb popular products such as hamburger patties, McNuggets, fish-flavored hamburger patties, potato pancakes, pumpkin pancakes, and meat skewers. It is an ideal breadcrumb equipment for fast food restaurants, distribution centers, and food factories.Features

1.Excellent crumbs circulation system virtually reduce the cutting damage of the crumbs,easy to realize the standard production.

2.Reliable protection device.

3.Siemens electric apparatus

4. Access to former,battering machine and fryer for continous production line

5.Stainless steel made,creative design,reasonable structure and reliable characteristicsSpecification

Model

XZSXJ200

XZSXJ400

XZSXJ600

Speed of the belt

3-15m/min adjustable

3-15m/min adjustable

3-15m/min adjustable

Power

1.1kw

1.85kw

3.45kw

Input height

1050±50 mm

1050±50 mm

1050±50 mm

Out put height

1050±50 mm

1050±50 mm

1050±50mm

Width of belt

200mm

400mm

600mm

Overall dimension

1700*680*1500mm

2600*880*2100mm

2600*880*2100mm

Tunnel Type Breading Machine

Still deciding? Get samples first, Contact US !

- Details

-

Product Description

The tunnel breading machine is a pre-treatment equipment in the processing of fried products. Its function is to evenly coat the products with breadcrumbs, which protect the fried products and enhance their color and flavor. It is an indispensable equipment in the processing of fried products. The breadcrumb machine can be used in conjunction with the battering machine or independently. It can be used to breadcrumb popular products such as hamburger patties, McNuggets, fish-flavored hamburger patties, potato pancakes, pumpkin pancakes, and meat skewers. It is an ideal breadcrumb equipment for fast food restaurants, distribution centers, and food factories.Features

1.Excellent crumbs circulation system virtually reduce the cutting damage of the crumbs,easy to realize the standard production.

2.Reliable protection device.

3.Siemens electric apparatus

4. Access to former,battering machine and fryer for continous production line

5.Stainless steel made,creative design,reasonable structure and reliable characteristicsSpecification

Model

XZSXJ200

XZSXJ400

XZSXJ600

Speed of the belt

3-15m/min adjustable

3-15m/min adjustable

3-15m/min adjustable

Power

1.1kw

1.85kw

3.45kw

Input height

1050±50 mm

1050±50 mm

1050±50 mm

Out put height

1050±50 mm

1050±50 mm

1050±50mm

Width of belt

200mm

400mm

600mm

Overall dimension

1700*680*1500mm

2600*880*2100mm

2600*880*2100mm

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!