Category

Share to

Automatic Batter Sparying Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

Product Description

The automatic batter spraying machine is a fully automatic coating equipment,which can automatically complete the sizing process of the product. The product is clamped by the upper and lower mesh belts of the sizing machine, completely immersed in the V.shaped slurry tank, fully impregnated and coated, so that the product is coated with a layer of slurry, it is suitable for wrappedfried food,tempura products, poultry, seafood, vegetables and other products.

Feature

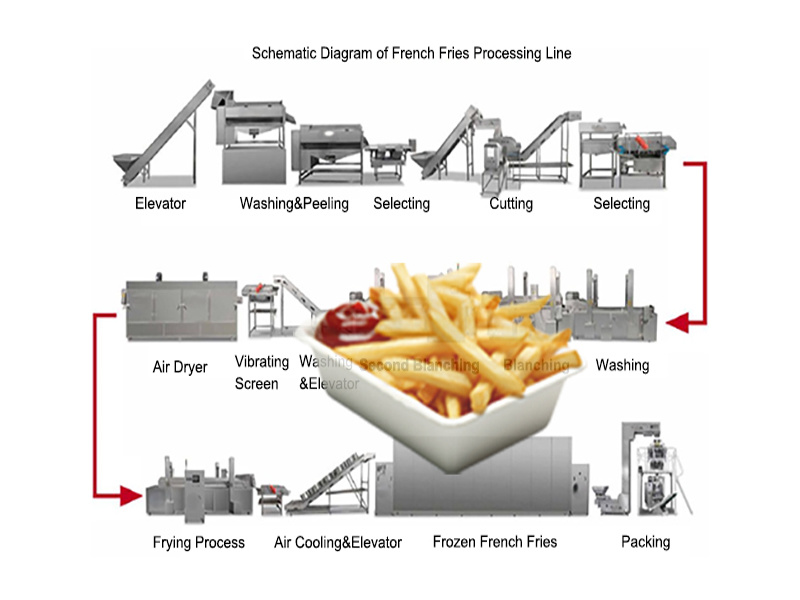

1.Efficient automated productionBy adopting the waterfall-style pulp curtain or immersion design, continuous operations are achieved, with the capacity to process hundreds to thousands of products per hour, significantly enhancing efficiency.The entire process is fully automated, including sizing, conveying, and recycling. It reduces the need for manual intervention and is suitable for large-scale assembly line operations.2. Uniform coating and precise controlBy adjusting the speed of the conveyor belt, the viscosity of the slurry, and the spacing of the mesh belt, ensure that the slurry evenly covers the surface of the ingredients, including areas with folds or complex shapes.Some models support variable frequency speed control and pulp volume control, which can handle different thicknesses or viscosities of pastes (such as egg liquid and batter)3. Multi-functional AdaptabilitySuitable for coating various ingredients such as meat (chicken cutlets, fish fillets), vegetables (lotus root sticks, french fries), and baked goods (bread slices) for coating purposes.It can be combined with subsequent processes such as frying or coating with batter, forming a complete processing line (such as a "drenching → frying → draining oil" assembly line)4. Hygiene and Safety DesignMade of all stainless steel, it complies with food-grade standards. Some models are equipped with a pulp chamber with an ice layer to maintain low temperature and prevent the pulp from deteriorating.Automatically recover excess slurry, reduce waste, and simultaneously lower the risk of cross-contamination.5. Flexibility and ScalabilitySupports customized molds or nozzles to accommodate various shapes (strip-like, sheet-like, block-like) of ingredientsIt can be integrated into the existing production line, such as being linked with the molding machine and the frying machine, to achieve full-process automation.Advantage

1 Special design of batter pump can greatly reduce the cutting of the batter

2 Fast-combine design, easy to clean, less damage to the viscosity of the batter.

3 SIEMENS electric apparatus guarantee the safety and reliability.

4 Can be precisely combined to a forming machine, a breading machine or a fryer to realize the continuous producing.

5 Stainless steel made, creative design, reasonable structure and reliable features.Specification

PModel

XZSJJ200

XZSJJ400

XZSJJ600

Speed of the belt

4-20m/min adjustable

4-20m/min adjustable

4-20m/min adjustable

Power

1 kw

1.3 kw

2.2kw

Input height

1050±50 mm

1050±50 mm

1050±50 mm

Out put height

1050 ±50 mm

1050±50 mm

1050±50mm

Width of belt

200mm

400mm

600mm

Overall dimension

1400*760*680mm

3020*1080*1250

3020*1080*1250

Automatic Batter Sparying Machine

Still deciding? Get samples first, Contact US !

- Details

-

Product Description

The automatic batter spraying machine is a fully automatic coating equipment,which can automatically complete the sizing process of the product. The product is clamped by the upper and lower mesh belts of the sizing machine, completely immersed in the V.shaped slurry tank, fully impregnated and coated, so that the product is coated with a layer of slurry, it is suitable for wrappedfried food,tempura products, poultry, seafood, vegetables and other products.

Feature

1.Efficient automated productionBy adopting the waterfall-style pulp curtain or immersion design, continuous operations are achieved, with the capacity to process hundreds to thousands of products per hour, significantly enhancing efficiency.The entire process is fully automated, including sizing, conveying, and recycling. It reduces the need for manual intervention and is suitable for large-scale assembly line operations.2. Uniform coating and precise controlBy adjusting the speed of the conveyor belt, the viscosity of the slurry, and the spacing of the mesh belt, ensure that the slurry evenly covers the surface of the ingredients, including areas with folds or complex shapes.Some models support variable frequency speed control and pulp volume control, which can handle different thicknesses or viscosities of pastes (such as egg liquid and batter)3. Multi-functional AdaptabilitySuitable for coating various ingredients such as meat (chicken cutlets, fish fillets), vegetables (lotus root sticks, french fries), and baked goods (bread slices) for coating purposes.It can be combined with subsequent processes such as frying or coating with batter, forming a complete processing line (such as a "drenching → frying → draining oil" assembly line)4. Hygiene and Safety DesignMade of all stainless steel, it complies with food-grade standards. Some models are equipped with a pulp chamber with an ice layer to maintain low temperature and prevent the pulp from deteriorating.Automatically recover excess slurry, reduce waste, and simultaneously lower the risk of cross-contamination.5. Flexibility and ScalabilitySupports customized molds or nozzles to accommodate various shapes (strip-like, sheet-like, block-like) of ingredientsIt can be integrated into the existing production line, such as being linked with the molding machine and the frying machine, to achieve full-process automation.Advantage

1 Special design of batter pump can greatly reduce the cutting of the batter

2 Fast-combine design, easy to clean, less damage to the viscosity of the batter.

3 SIEMENS electric apparatus guarantee the safety and reliability.

4 Can be precisely combined to a forming machine, a breading machine or a fryer to realize the continuous producing.

5 Stainless steel made, creative design, reasonable structure and reliable features.Specification

PModel

XZSJJ200

XZSJJ400

XZSJJ600

Speed of the belt

4-20m/min adjustable

4-20m/min adjustable

4-20m/min adjustable

Power

1 kw

1.3 kw

2.2kw

Input height

1050±50 mm

1050±50 mm

1050±50 mm

Out put height

1050 ±50 mm

1050±50 mm

1050±50mm

Width of belt

200mm

400mm

600mm

Overall dimension

1400*760*680mm

3020*1080*1250

3020*1080*1250

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!