Category

Share to

Small Potato Chips Frying Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

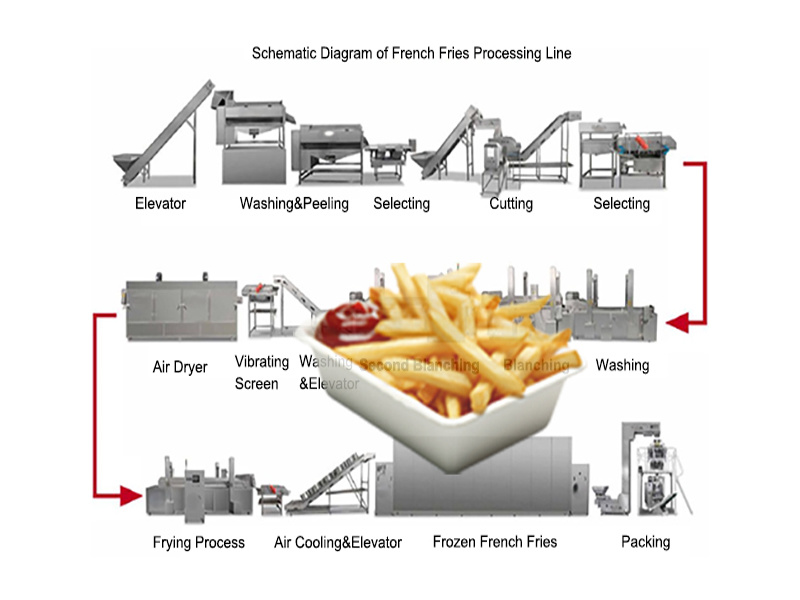

Automatic Potato Chips Fryer Machine

1. Automatic feeding, automatic mixing, automatic discharging, saving manpower, ensuring consistent product color and taste, low noise, high efficiency, and durability.

2. The electric heating system adopts U-shaped heating tubes, evenly distributed in the oil, and uniformly heated. Fast heating, corrosion resistance, and long service life.

3. Automatic mixing adopts self rotation and revolution to ensure the uniformity of product frying and prevent products from sticking to each other due to compression

4. Install an automatic thermostat on the device, and the operator only needs to set the temperature to achieve automatic temperature control. The temperature can be adjusted

5. During the frying process, all the residue generated by the frying machine sinks into low-temperature water, fundamentally solving the problem of important factors such as the burning of residue and the oxidation and blackening of high-temperature oil in traditional frying machines.

6. Adopting the internationally recognized oil-water mixing process design, it saves more cooking oil compared to ordinary deep fryers. Extend the service life of edible oil;

7. The food residue generated during the frying process of this frying equipment can be filtered through water and deposited into the bottom funnel, and discharged through the drain outlet. This not only achieves the function of filtering oil, but also does not waste oil;

8. Compared with ordinary frying machines, the food fried by this machine does not contain heavy metals or other harmful substances to the human body;

9. Equipment operation is simple and efficient

According to the needs of different customers, we can provide different heating methods, such as electric heating, gas heating, etc.We support customizing relevant machines according to customer needs. Here are some common device parameters for reference.

Model

Overall Dimension

Basket Dimension

Internal Groove Size

Heating Style

Oil Capacity

Feeding/Discharge/Mixing Power

Frying Temperature

Basket Flipping Height

1200

2000×1900×1500mm

1200×450mm (Diameter*Depth)

1200×430(Diameter*Depth)

Electric/ 60kw

440L

Automatic 1.1/0.75/0.55kw

0-280°C Adjstable

2300mm

1500

2600×2300×1500mm

1500×410(Diameter*Depth)

1500×1500×400mm

Gas/100000kcal

530L

Automatic 1.5/0.75/0.55kw

0-280°C Adjstable

2650mm

Application

Suitable for fast food restaurants, canteens, chain stores, supermarkets; Small and medium-sized fried food processing enterprises are widely used in the deep frying processing of meat, seafood, vegetables, pasta and other foods.

1. Noodles. Fried Dough Twists, crispy rice, honey food, honey three knives, deep-fried dough sticks, dough, gluten, rice noodles, Sachima, Nenzi, Cat's ears (Steamed cat-ear shaped bread)

2. Carnivorous products.Grilled chicken (colored), salted duck (colored), Braised pork belly in brown sauce, meatballs, beef jerky, streaky pork, chicken legs, pig hooves, fried fish, chicken and duck by-products

3. Nuts. Peanut, green beans, broad beans, sunflower seeds

4. Bean products.Douqian, Doupao, Fish Tofu, Bean Ginseng

5. Seafood products. Various fish, shrimp, scallops, rainbow, small fry, squid rings, squid fry

6. Other categories. Vegetable cakes, tempura, tomato boxes, lotus roots, and various fried and puffed foods with paste and paste

Small Potato Chips Frying Machine

Still deciding? Get samples first, Contact US !

- Details

-

Automatic Potato Chips Fryer Machine

1. Automatic feeding, automatic mixing, automatic discharging, saving manpower, ensuring consistent product color and taste, low noise, high efficiency, and durability.

2. The electric heating system adopts U-shaped heating tubes, evenly distributed in the oil, and uniformly heated. Fast heating, corrosion resistance, and long service life.

3. Automatic mixing adopts self rotation and revolution to ensure the uniformity of product frying and prevent products from sticking to each other due to compression

4. Install an automatic thermostat on the device, and the operator only needs to set the temperature to achieve automatic temperature control. The temperature can be adjusted

5. During the frying process, all the residue generated by the frying machine sinks into low-temperature water, fundamentally solving the problem of important factors such as the burning of residue and the oxidation and blackening of high-temperature oil in traditional frying machines.

6. Adopting the internationally recognized oil-water mixing process design, it saves more cooking oil compared to ordinary deep fryers. Extend the service life of edible oil;

7. The food residue generated during the frying process of this frying equipment can be filtered through water and deposited into the bottom funnel, and discharged through the drain outlet. This not only achieves the function of filtering oil, but also does not waste oil;

8. Compared with ordinary frying machines, the food fried by this machine does not contain heavy metals or other harmful substances to the human body;

9. Equipment operation is simple and efficient

According to the needs of different customers, we can provide different heating methods, such as electric heating, gas heating, etc.We support customizing relevant machines according to customer needs. Here are some common device parameters for reference.

Model

Overall Dimension

Basket Dimension

Internal Groove Size

Heating Style

Oil Capacity

Feeding/Discharge/Mixing Power

Frying Temperature

Basket Flipping Height

1200

2000×1900×1500mm

1200×450mm (Diameter*Depth)

1200×430(Diameter*Depth)

Electric/ 60kw

440L

Automatic 1.1/0.75/0.55kw

0-280°C Adjstable

2300mm

1500

2600×2300×1500mm

1500×410(Diameter*Depth)

1500×1500×400mm

Gas/100000kcal

530L

Automatic 1.5/0.75/0.55kw

0-280°C Adjstable

2650mm

Application

Suitable for fast food restaurants, canteens, chain stores, supermarkets; Small and medium-sized fried food processing enterprises are widely used in the deep frying processing of meat, seafood, vegetables, pasta and other foods.

1. Noodles. Fried Dough Twists, crispy rice, honey food, honey three knives, deep-fried dough sticks, dough, gluten, rice noodles, Sachima, Nenzi, Cat's ears (Steamed cat-ear shaped bread)

2. Carnivorous products.Grilled chicken (colored), salted duck (colored), Braised pork belly in brown sauce, meatballs, beef jerky, streaky pork, chicken legs, pig hooves, fried fish, chicken and duck by-products

3. Nuts. Peanut, green beans, broad beans, sunflower seeds

4. Bean products.Douqian, Doupao, Fish Tofu, Bean Ginseng

5. Seafood products. Various fish, shrimp, scallops, rainbow, small fry, squid rings, squid fry

6. Other categories. Vegetable cakes, tempura, tomato boxes, lotus roots, and various fried and puffed foods with paste and paste

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!