Category

Share to

Continuous Chicken Nugget Frying Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

Product Description

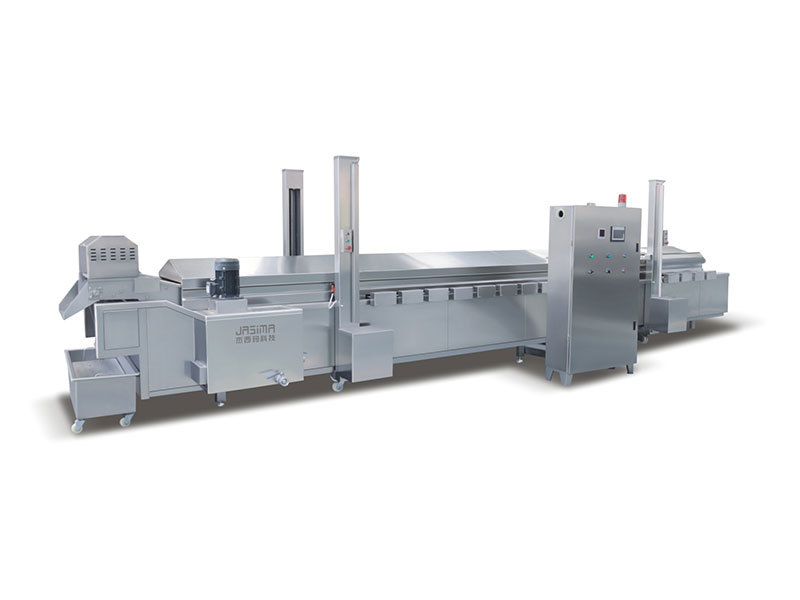

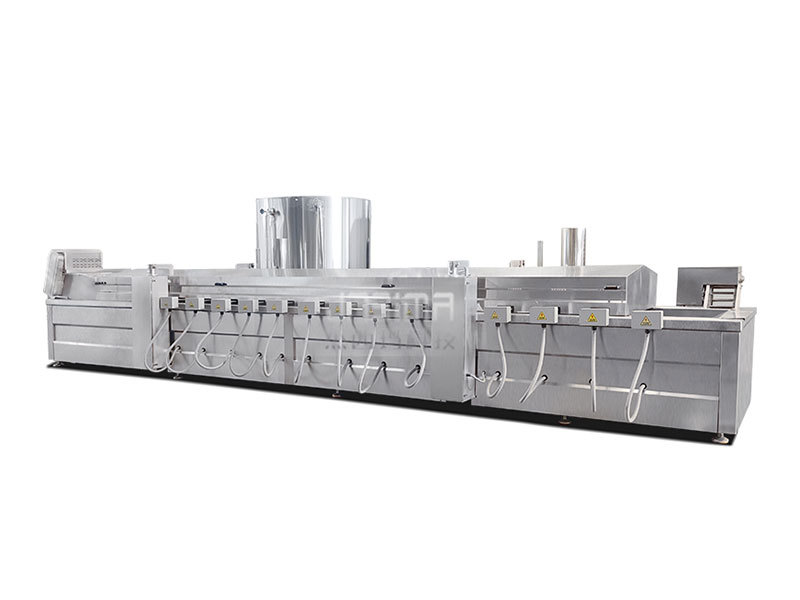

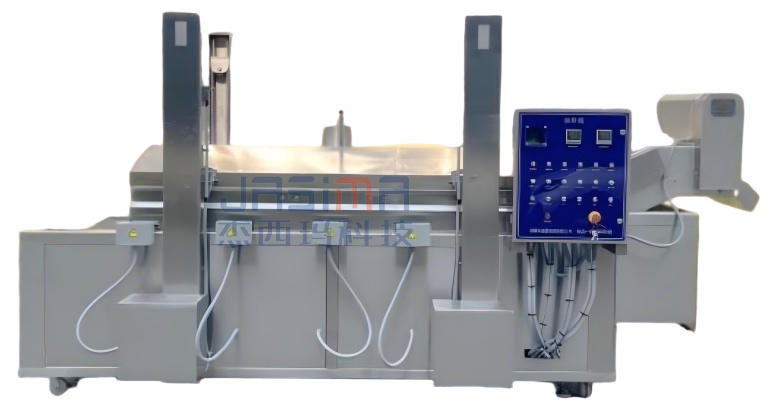

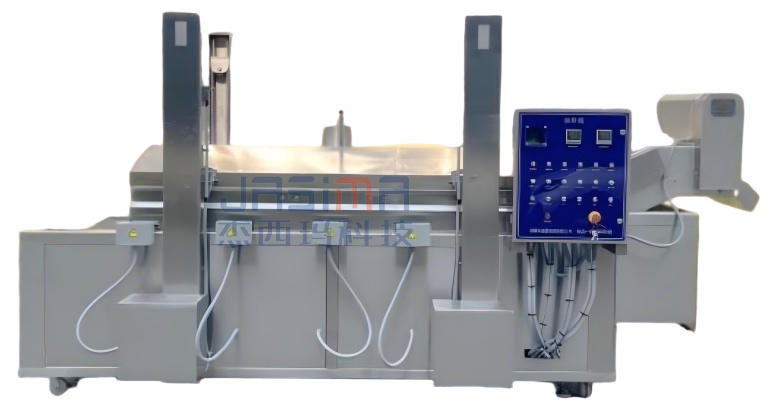

Our Chicken Frying Machine adopts pure oil frying technology, equipped with a dynamic bottom scraping and filtering system, with a circulation device, to automatically filter and remove slag during operation, ensuring the quality of frying oil. It is made of high-quality 304 stainless steel and equipped with an automatic lifting function, which is conducive to cleaning and hygiene. It uses double mesh belts to transport products, preventing uneven frying due to light floating. The upper and lower mesh belts can be adjusted by frequency conversion. Simultaneously equipped with a carbon dioxide fire extinguishing device.

Fried Chicken Fryer Machine Features

1. Mesh belt transmission adopts frequency infinitely adjustable-speed, frying time can be controlled.

2. Equipment with automatic lifting system, all stainless steel design, clean and safe.

3. At the bottom , there is the waste discharge which c an automatically discharge dregs

4. Use upper and lower double mesh belt transmission, can avoid the floater

5. Our this model machine have oil circulation filter system,can continuously filtered oil residue, and extend the service life of cooking oil.Fried Chicken Making Machine Specifications

Oil capacity

800L( with oil tank)

Dimensions

4000*1500*1900mm

Mesh belt

SUS 304 Mesh Belt

Width of mesh belt

800mm

Frying temperature

160-185°C

Max frying temperature

220°C

Heating method

Electric

Temperature control accuracy

±1℃

Conveyor belt form

Tunnel type chain driven stainless steel mesh belt

Deatailed Parts Introduction

Machine’s Body Part

The pot body is made of 5mm stainless steel plate and made of 304 material. The shell of the pot body is made of 2.0mm stainless steel plate material, which is 304.. After welding the pot body, conduct an hourglass test to ensure that there is no leakage.The main material of the pot body is stainless steel and other materials suitable for the food industry.. Aluminum silicate insulation material is installed between the pot body and the shell.Install a drain valve at the lowest point of the pot body.

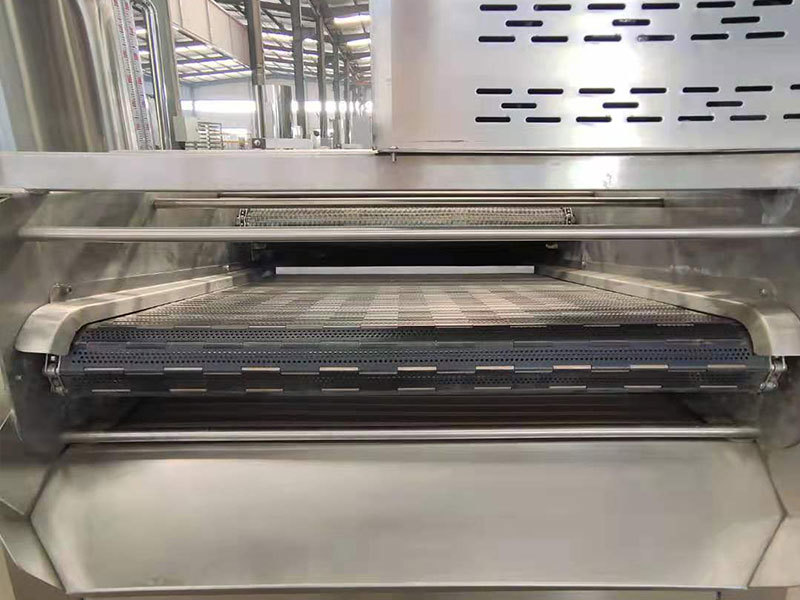

Conveyor Belt and Conveyor Belt Bracket

Variable frequency speed control of conveyor belt.The conveyor belt bracket is made of 5mm stainless steel cold bending butt joint.The oil fume hood and conveyor bracket can be lifted independently for easy cleaning.The bearings and bearing seats are made of stainless steel material.The gap between the upper and lower mesh belts is adjustable by 80mm.

Oil Fume Exhaust Section and Upgrade Section

The exhaust hood is assembled with 1.5mm stainless steel plates and has a pointed structure as a whole. The oil fume hood and exhaust pipe are equipped with a condensate drainage structure made of 304 material.

Using a worm gear reducer for lifting, two sets of lifting are available. The exhaust hood can be lifted separately as needed or together with the mesh belt bracket for easy cleaning of the conveyor belt and exhaust hood.

Heating Section and Scraping Part

Two temperature control points to accurately grasp the frying temperature during operation.The equipment adopts a bottom scraping and slag removal design to ensure that the residue settled at the bottom of the oil can be removed and separated to the outside of the equipment in a timely manner, ensuring that the edible oil will not cause aging, black oil and other phenomena due to residue carbonization.The bottom of the equipment is driven by a chain and scraped with a scraper plate. Ensure the scraping effect.

Electric Control Part and Oil Storage Tank Section

The electrical control cabinet is made of stainless steel material, with a plate thickness of 1.5mm and a material of 304. Equipped with emergency stop switch, main leakage protection switch, and over temperature alarm. Use Delixi brand leakage protection switches, AC contactors, Yudian brand temperature controllers, and Schneider brand frequency converters.

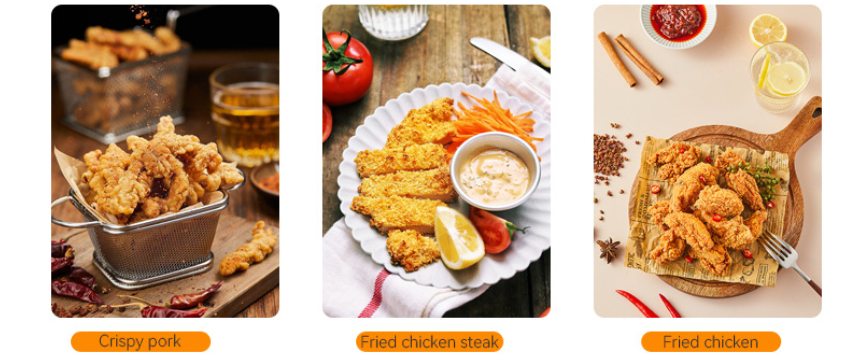

Applicaiton Ranges

1.Leisure Snacks

Puffed foods: french fries, potato chips, shrimp strips, corn chips, etc

Nuts: fried peanuts, broad beans, cashews, etc

Fruit and vegetable chips: banana chips, apple chips (requiring low-temperature vacuum frying technology)

2.Fast Food and pre Made Meals

Meat products: chicken rice flower, chicken steak, fish steak, meatballs, tiger skin chicken feet, etc

Quick frozen food: pre fried Spring rolls, deep-fried dough sticks, tempura (need to be heated twice)

Aquatic products: fried fish balls, squid rings, shrimp cakes, etc

3.Traditional and Specialty Foods

Bean products: fried dried tofu, bean curd, soy protein, etc

Noodles: Rice Noodles, Cat's ears (Steamed cat-ear shaped bread), Sachima, Fried Dough Twists, etc

International features: such as Hushpuppies from the southern United States, Jalebi from India, Tempura from Japan, etc

Continuous Chicken Nugget Frying Machine

Still deciding? Get samples first, Contact US !

- Details

-

Product Description

Our Chicken Frying Machine adopts pure oil frying technology, equipped with a dynamic bottom scraping and filtering system, with a circulation device, to automatically filter and remove slag during operation, ensuring the quality of frying oil. It is made of high-quality 304 stainless steel and equipped with an automatic lifting function, which is conducive to cleaning and hygiene. It uses double mesh belts to transport products, preventing uneven frying due to light floating. The upper and lower mesh belts can be adjusted by frequency conversion. Simultaneously equipped with a carbon dioxide fire extinguishing device.

Fried Chicken Fryer Machine Features

1. Mesh belt transmission adopts frequency infinitely adjustable-speed, frying time can be controlled.

2. Equipment with automatic lifting system, all stainless steel design, clean and safe.

3. At the bottom , there is the waste discharge which c an automatically discharge dregs

4. Use upper and lower double mesh belt transmission, can avoid the floater

5. Our this model machine have oil circulation filter system,can continuously filtered oil residue, and extend the service life of cooking oil.Fried Chicken Making Machine Specifications

Oil capacity

800L( with oil tank)

Dimensions

4000*1500*1900mm

Mesh belt

SUS 304 Mesh Belt

Width of mesh belt

800mm

Frying temperature

160-185°C

Max frying temperature

220°C

Heating method

Electric

Temperature control accuracy

±1℃

Conveyor belt form

Tunnel type chain driven stainless steel mesh belt

Deatailed Parts Introduction

Machine’s Body Part

The pot body is made of 5mm stainless steel plate and made of 304 material. The shell of the pot body is made of 2.0mm stainless steel plate material, which is 304.. After welding the pot body, conduct an hourglass test to ensure that there is no leakage.The main material of the pot body is stainless steel and other materials suitable for the food industry.. Aluminum silicate insulation material is installed between the pot body and the shell.Install a drain valve at the lowest point of the pot body.

Conveyor Belt and Conveyor Belt Bracket

Variable frequency speed control of conveyor belt.The conveyor belt bracket is made of 5mm stainless steel cold bending butt joint.The oil fume hood and conveyor bracket can be lifted independently for easy cleaning.The bearings and bearing seats are made of stainless steel material.The gap between the upper and lower mesh belts is adjustable by 80mm.

Oil Fume Exhaust Section and Upgrade Section

The exhaust hood is assembled with 1.5mm stainless steel plates and has a pointed structure as a whole. The oil fume hood and exhaust pipe are equipped with a condensate drainage structure made of 304 material.

Using a worm gear reducer for lifting, two sets of lifting are available. The exhaust hood can be lifted separately as needed or together with the mesh belt bracket for easy cleaning of the conveyor belt and exhaust hood.

Heating Section and Scraping Part

Two temperature control points to accurately grasp the frying temperature during operation.The equipment adopts a bottom scraping and slag removal design to ensure that the residue settled at the bottom of the oil can be removed and separated to the outside of the equipment in a timely manner, ensuring that the edible oil will not cause aging, black oil and other phenomena due to residue carbonization.The bottom of the equipment is driven by a chain and scraped with a scraper plate. Ensure the scraping effect.

Electric Control Part and Oil Storage Tank Section

The electrical control cabinet is made of stainless steel material, with a plate thickness of 1.5mm and a material of 304. Equipped with emergency stop switch, main leakage protection switch, and over temperature alarm. Use Delixi brand leakage protection switches, AC contactors, Yudian brand temperature controllers, and Schneider brand frequency converters.

Applicaiton Ranges

1.Leisure Snacks

Puffed foods: french fries, potato chips, shrimp strips, corn chips, etc

Nuts: fried peanuts, broad beans, cashews, etc

Fruit and vegetable chips: banana chips, apple chips (requiring low-temperature vacuum frying technology)

2.Fast Food and pre Made Meals

Meat products: chicken rice flower, chicken steak, fish steak, meatballs, tiger skin chicken feet, etc

Quick frozen food: pre fried Spring rolls, deep-fried dough sticks, tempura (need to be heated twice)

Aquatic products: fried fish balls, squid rings, shrimp cakes, etc

3.Traditional and Specialty Foods

Bean products: fried dried tofu, bean curd, soy protein, etc

Noodles: Rice Noodles, Cat's ears (Steamed cat-ear shaped bread), Sachima, Fried Dough Twists, etc

International features: such as Hushpuppies from the southern United States, Jalebi from India, Tempura from Japan, etc

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!