Category

Share to

Small Capacity Chicken Nugget Production Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details

-

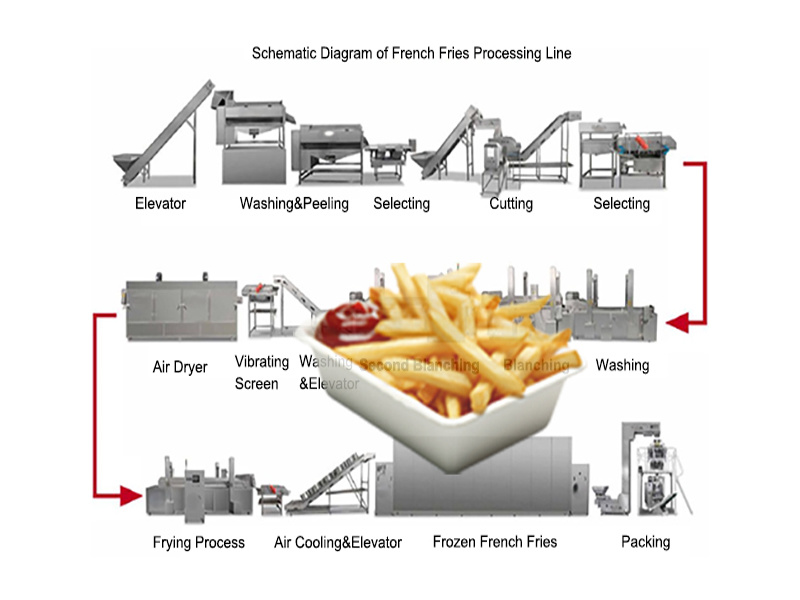

The small chicken nugget production line is a complete set of equipment used in modern food processing industry for continuous and automated production of fried chicken nuggets. Its core functions include raw material processing, chicken nugget forming, chicken nugget battering, chicken nugget breading ,chicken nugget frying, air cooling, as well as quick freezing, and packaging, aiming to improve production efficiency and ensure food safety.

Chicken Nugget Production Process

1.Forming Machine.

Automatic Forming Machine can make chicken nugget ,burger patty as well as fish patty, shrimp and potato patty, vegetable ,pumpkin patty and other foods.It is fast, low noise, safe, reliable, compact structure, very easy to maintain. According to the forming machine drive structure and forming principle, specifications, sizes and shapes of molding products can be met by replacing different molds.

2. Chicken Nugget Battering

After the chicken nugget forming, they will be placed on the chicken nugget battering machine's conveyor belt and the conveyor belt carries the product slowly through the slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity. The chicken nugget batter coating machine is made of food grade SUS304 stainless steel (including screws, nuts and other components), long-term use does not rust, does not corrode.The battering slurry machine consists of two layers of conveyor belt, slurry groove, wind knife and other structures, suitable for slurry of different thickness and viscosity.

3.Chicken Nugget Breading Machine.

The chicken nugget breading machine can automatically completes the process of the chicken nugget breading. It has excellent circulation system, greatly reduces the breakage of crumbs; not only suitable for crumbs, but also suitable for coarse crumbs. The breading machine adopts variable frequency adjustment, easy operation.

4.Chicken Nugget Frying Machine.

We adopt continuous frying machine to make sure the quality of the chicken nuggest frying time and temperature.The chicken nuggets frying machine adopts pure oil frying process, equipped with a dynamic bottom scraping slag filtration system, with a circulating device, to achieve automatic filtration of slag in the process of work, to ensure the quality of frying .In addition, our frying machine also adopts double mesh belt to convey products, prevent products from being uneven due to light floating frying.

6.Air Cooling Machine.

After frying, the fried chicken bugget will be through a air cooling line to lower the temperature and then go to the next process,such as quick freezing.

Machine's Paremeter

Product Name

Dimension(mm)

Power

Material

Forming Machine

860*600*1400mm0.55KW

SUS 304

Battring Machine

1400*760*680mm1KW

SUS 304

Breading Machine

1200*700*950mm

1.1KW

SUS 304

Frying Machine

1400*1400*1850mm

60KW

SUS 304

Air Cooling Machine

1700*680*1500mm

2.1kw

SUS 304

Product Features

The fully automatic chicken nugget maker with features of small output, user-friendly operation, and convenient cleaning. Customized molds of chicken nugget machine can be easily replaced to accommodate a variety of shapes and sizes (round, square, heart, triangle, etc.). The chicken nugget production line is not only suitable for making chicken nuggets, but also for making fish nuggets, hamburger patties, pumpkin patties, potato patties and other fried products. It is suitable for use in large-scale, medium-sized and small factories, as well as fast food restaurants, etc.

The chicken nugget production line is not only suitable for making chicken nuggets, but also for making fish nuggets, hamburger patties, pumpkin patties, potato patties and other fried products. It is suitable for use in large-scale, medium-sized and small factories, as well as fast food restaurants, etc.

- Details

-

The small chicken nugget production line is a complete set of equipment used in modern food processing industry for continuous and automated production of fried chicken nuggets. Its core functions include raw material processing, chicken nugget forming, chicken nugget battering, chicken nugget breading ,chicken nugget frying, air cooling, as well as quick freezing, and packaging, aiming to improve production efficiency and ensure food safety.

Chicken Nugget Production Process

1.Forming Machine.

Automatic Forming Machine can make chicken nugget ,burger patty as well as fish patty, shrimp and potato patty, vegetable ,pumpkin patty and other foods.It is fast, low noise, safe, reliable, compact structure, very easy to maintain. According to the forming machine drive structure and forming principle, specifications, sizes and shapes of molding products can be met by replacing different molds.

2. Chicken Nugget Battering

After the chicken nugget forming, they will be placed on the chicken nugget battering machine's conveyor belt and the conveyor belt carries the product slowly through the slurry groove, so that the product is wrapped in slurry, suitable for slurry of different thickness and viscosity. The chicken nugget batter coating machine is made of food grade SUS304 stainless steel (including screws, nuts and other components), long-term use does not rust, does not corrode.The battering slurry machine consists of two layers of conveyor belt, slurry groove, wind knife and other structures, suitable for slurry of different thickness and viscosity.

3.Chicken Nugget Breading Machine.

The chicken nugget breading machine can automatically completes the process of the chicken nugget breading. It has excellent circulation system, greatly reduces the breakage of crumbs; not only suitable for crumbs, but also suitable for coarse crumbs. The breading machine adopts variable frequency adjustment, easy operation.

4.Chicken Nugget Frying Machine.

We adopt continuous frying machine to make sure the quality of the chicken nuggest frying time and temperature.The chicken nuggets frying machine adopts pure oil frying process, equipped with a dynamic bottom scraping slag filtration system, with a circulating device, to achieve automatic filtration of slag in the process of work, to ensure the quality of frying .In addition, our frying machine also adopts double mesh belt to convey products, prevent products from being uneven due to light floating frying.

6.Air Cooling Machine.

After frying, the fried chicken bugget will be through a air cooling line to lower the temperature and then go to the next process,such as quick freezing.

Machine's Paremeter

Product Name

Dimension(mm)

Power

Material

Forming Machine

860*600*1400mm0.55KW

SUS 304

Battring Machine

1400*760*680mm1KW

SUS 304

Breading Machine

1200*700*950mm

1.1KW

SUS 304

Frying Machine

1400*1400*1850mm

60KW

SUS 304

Air Cooling Machine

1700*680*1500mm

2.1kw

SUS 304

Product Features

The fully automatic chicken nugget maker with features of small output, user-friendly operation, and convenient cleaning. Customized molds of chicken nugget machine can be easily replaced to accommodate a variety of shapes and sizes (round, square, heart, triangle, etc.). The chicken nugget production line is not only suitable for making chicken nuggets, but also for making fish nuggets, hamburger patties, pumpkin patties, potato patties and other fried products. It is suitable for use in large-scale, medium-sized and small factories, as well as fast food restaurants, etc.

The chicken nugget production line is not only suitable for making chicken nuggets, but also for making fish nuggets, hamburger patties, pumpkin patties, potato patties and other fried products. It is suitable for use in large-scale, medium-sized and small factories, as well as fast food restaurants, etc.

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!