Category

Share to

Automatic Meat Cake Food Forming Machine

Still deciding? Get samples first, Contact US !

View similar products

- Details

-

Product Description

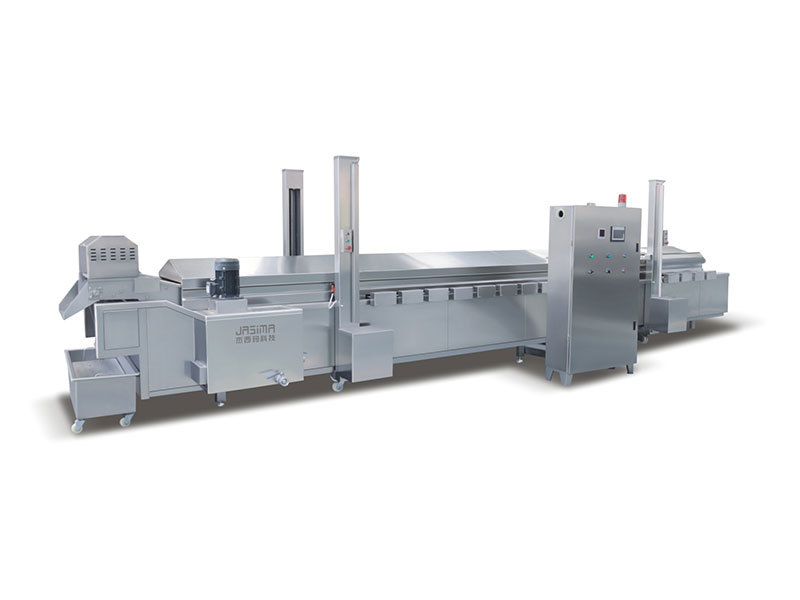

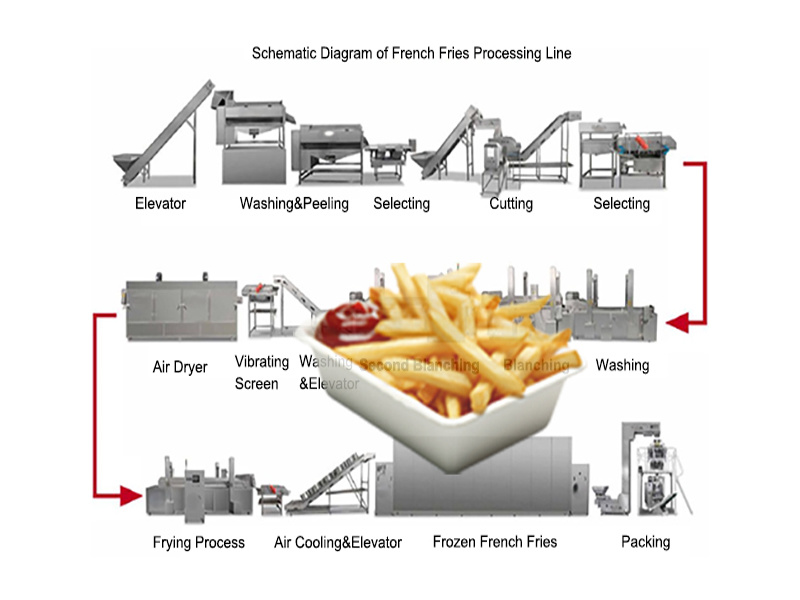

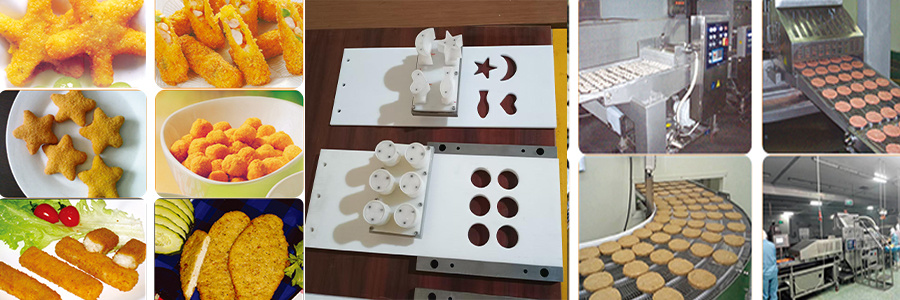

Automatic meat patty food forming machine can automatically perform various procedures such as meat filling, forming and output and form a fully automatic prepared food line when connected with the battering machine, preduster, frying machine, cooking machine, instant freezer and packing machine, sharing the good features of high production capacity and stable quality.Specification

Model

XZCXJ100

Specification

tank capacity 30L

Power

0.55KW

Belt width

130mm

Production capacity

35pcs/min

Overal dimention

860*600*1400mm

Burger Patty Forming Machine Feature

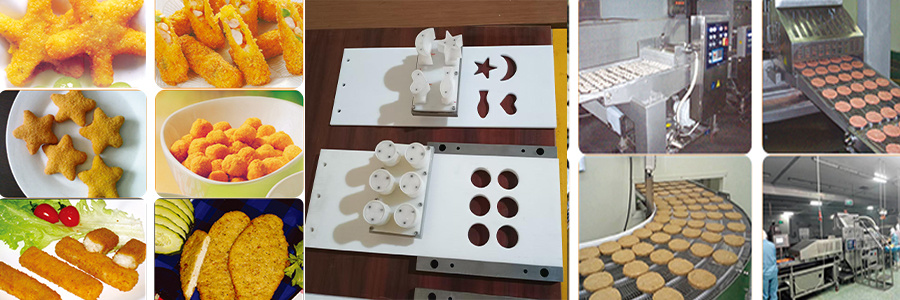

1.Multifunctionality

By changing the mold, different shapes of meat patties such as circular, square, and heart-shaped can be produced. The thickness adjustment range is usually 6-20 millimeters, and it is compatible with various raw materials, including beef, chicken, fish, potatoes, pumpkins, etc

2.Efficient automation

Automatic completion of filling, shaping, labeling (optional), conveying and other processes, some models integrate integrated meat grinding and shaping design, with a production efficiency of up to 2100 pieces/hour, significantly reducing labor costs

3.Health and Safety

Adopting food grade stainless steel and detachable component design, in compliance with HACCP hygiene standards, some models are equipped with induction shutdown switches to ensure operational safety

4.Customization capability

Supports single or double cake molding, and the mold can be customized to meet different specifications .It can be equipped with sizing machines, coating machines and other equipment to form a complete production line.Endless patterns can design for fabulous meat food products: round, square, ellipse, triangle, heart and some other patterns such as cartoon, star…

Automatic Meat Cake Food Forming Machine

Still deciding? Get samples first, Contact US !

- Details

-

Product Description

Automatic meat patty food forming machine can automatically perform various procedures such as meat filling, forming and output and form a fully automatic prepared food line when connected with the battering machine, preduster, frying machine, cooking machine, instant freezer and packing machine, sharing the good features of high production capacity and stable quality.Specification

Model

XZCXJ100

Specification

tank capacity 30L

Power

0.55KW

Belt width

130mm

Production capacity

35pcs/min

Overal dimention

860*600*1400mm

Burger Patty Forming Machine Feature

1.Multifunctionality

By changing the mold, different shapes of meat patties such as circular, square, and heart-shaped can be produced. The thickness adjustment range is usually 6-20 millimeters, and it is compatible with various raw materials, including beef, chicken, fish, potatoes, pumpkins, etc

2.Efficient automation

Automatic completion of filling, shaping, labeling (optional), conveying and other processes, some models integrate integrated meat grinding and shaping design, with a production efficiency of up to 2100 pieces/hour, significantly reducing labor costs

3.Health and Safety

Adopting food grade stainless steel and detachable component design, in compliance with HACCP hygiene standards, some models are equipped with induction shutdown switches to ensure operational safety

4.Customization capability

Supports single or double cake molding, and the mold can be customized to meet different specifications .It can be equipped with sizing machines, coating machines and other equipment to form a complete production line.Endless patterns can design for fabulous meat food products: round, square, ellipse, triangle, heart and some other patterns such as cartoon, star…

STRENGTH

Certification

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!